Changing the face of e-waste processing in the UK

It began as a single enquiry for an UNTHA RS30 four-shaft shredder, when The Royal Mint had a bold idea to change the face of e-waste processing in the UK. But several months later, thanks to the company’s innovative foresight –in collaboration with UNTHA and other engineering partners – this vision evolved into a complex, industry-first installation that has stopped the global WEEE recycling industry in its tracks.

Here, we explore how this groundbreaking operation, featuring three UNTHA shredders, unlocks the untapped potential of e-waste to drive sustainable precious metal liberation and economic growth.

Building British heritage for more than a millennium

As the official maker of UK coins, The Royal Mint’s legacy spans more than 1,100 years, making it the oldest company in the UK. Throughout this rich history, it has been synonymous with precision, engineering excellence, and an unwavering commitment to quality – from producing the nation’s coinage and commemorative medals to offering investment opportunities in gold and silver.

But as the world changes, so too do this historic institution’s ambitions. With cash usage declining and fewer people required for traditional coin production, The Royal Mint recognised the need to diversify its operations. At the same time, the UK has become the second-largest producer of e-waste per capita, trailing only Norway with its poor WEEE disposal habits. Addressing this mounting global challenge offered a timely opportunity to reduce overseas shipping of discarded electronics and retain the value of precious metals within the UK.

In doing so, the company has the capacity to process over 4,000 tonnes of printed circuit boards from e-waste annually and generate up to 450kg of gold each year – worth approximately £27 million at current prices (as of January 2024). Ultimately, it’s a testament to the historic institution’s ambition, showcasing how even the most traditional companies can evolve to drive groundbreaking solutions for sustainability and profitability.

The untapped potential ‘locked’ inside e-waste

Discarded electronics are piling up at an alarming rate globally, presenting a major challenge for waste management – not to mention the environment. And figures are expected to grow even further, with the United Nations predicting a 32% increase over the next few years, reaching 82 million tonnes per annum, by 2030. But within every piece of ‘redundant’ equipment – from mobile phones and computers to large kitchen appliances – lies a wealth of valuable materials to be liberated.

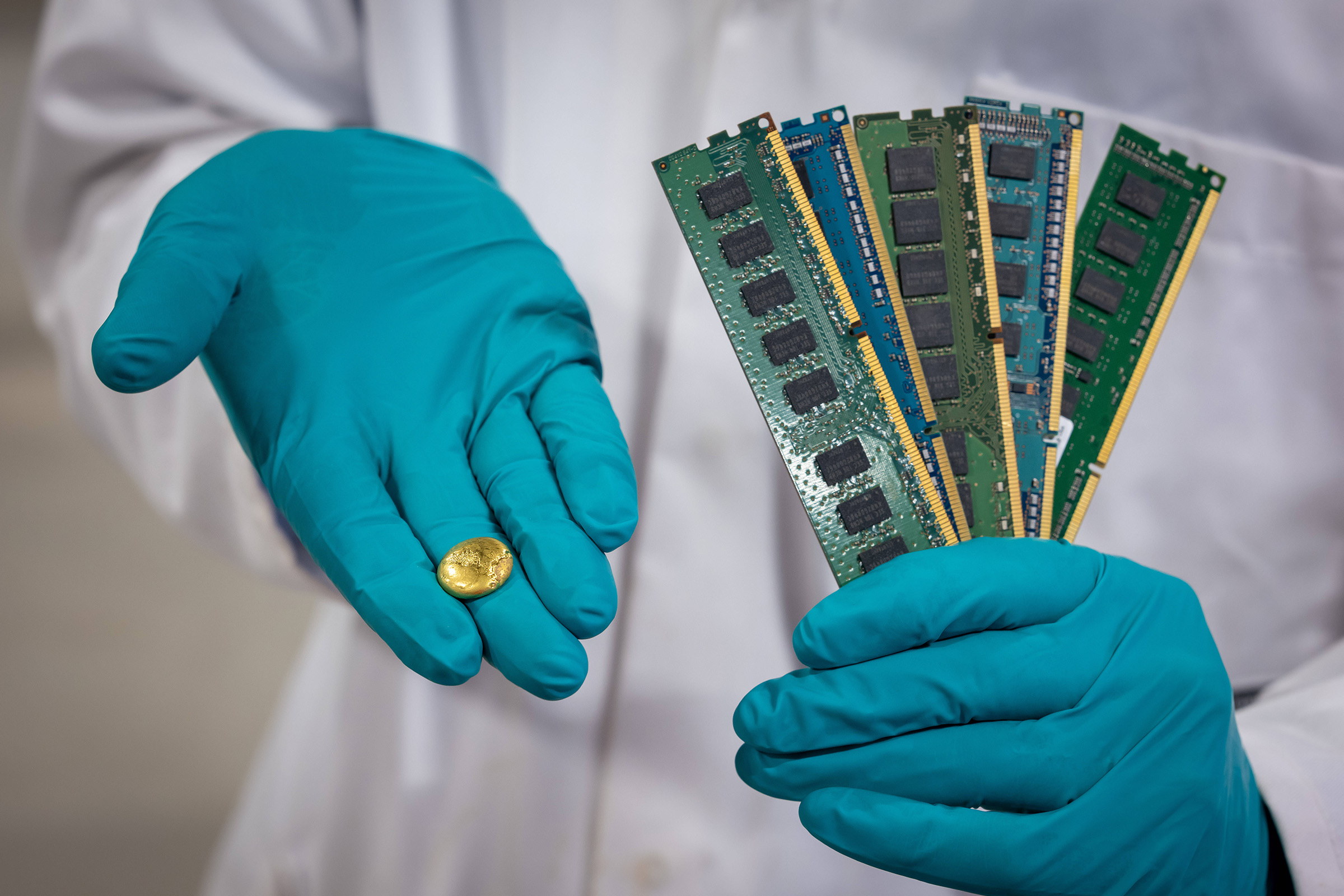

And not just base metals such as copper and aluminum. Constituent parts also include precious metals like gold, silver, and palladium. In fact, gold is found in much higher concentrations in e-waste than in raw ore. However, due to inefficient recycling processes, this risks these remaining ‘locked’ inside. But The Royal Mint’s groundbreaking facility sets a new precedent for WEEE recycling. By extracting and reusing precious metals found in printed circuit boards, the company is helping to close the loop on precious metal recovery and pave the way for a more circular economy.

An industry-first processing line

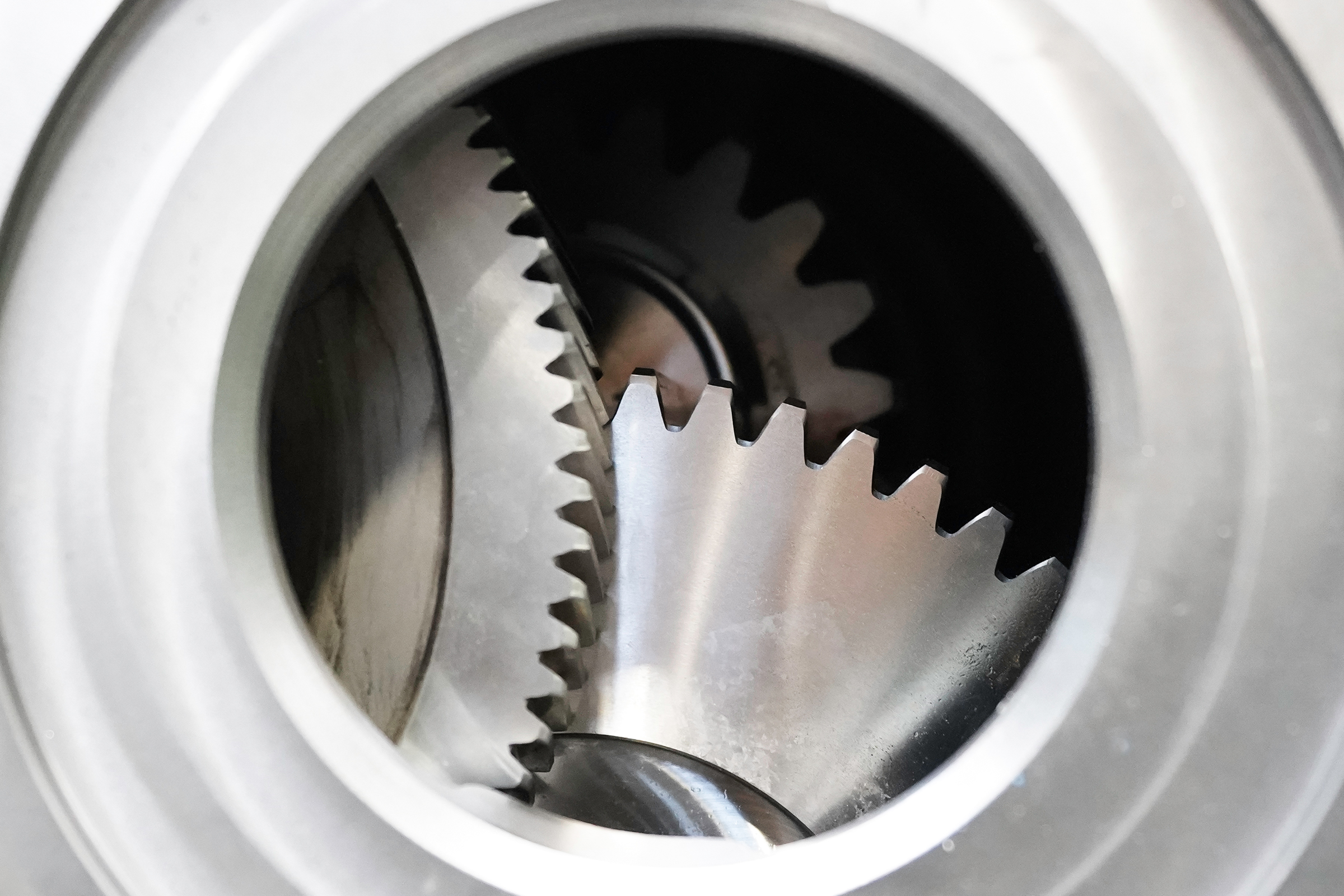

The beating heart of this multi-million-pound, 35-acre South Wales facility is an intricate, high-tech processing line that integrates the latest advancements in technology, including three UNTHA RS30 four-shaft shredders. With their precise, low-speed, high-torque design, the machines provide a controlled and efficient way to process e-waste – breaking down large, complex circuit boards into finely tuned granulate particles – while ensuring low emissions and minimal energy consumption. The shredded material is then ready for further downstream treatment, where a complex system of ancillary technologies further separates and refines different metallurgical content for maximum recovery.

Non-metal components are repurposed into building materials, while base metals are extracted and sold to refiners. But the treatment of precious metals is what truly sets this facility apart on the global stage. Leveraging ‘world-first’ patented chemistry from The Royal Mint’s Canadian clean-tech partner, Excir, gold fractions are selectively extracted, leaching out more than 99% of the gold ‘locked’ inside the input material. This gold is then recovered as a powder, which is later heated in a furnace to create gleaming nuggets, ready to be reintroduced into the supply chain to make new products. This is being used to craft jewelry for The Royal Mint’s luxury jewelry line, 886 by The Royal Mint.

This process contrasts sharply with traditional gold recovery methods, which are highly energy-intensive and rely on toxic chemicals or high-energy smelting that burn the materials. The Royal Mint’s approach instead uses a recyclable chemical solution at low energy, operating at room temperature to quickly and efficiently draw gold from the waste.

Driving circular manufacturing processes

The Royal Mint effectively transforms e-waste into a valuable resource, taking precious materials that would otherwise be buried in landfills and turning them into commodities that benefit industries beyond their own. By closing the loop on e-waste, this global leader reduces its carbon footprint, lessens reliance on mined materials, and pioneers a more sustainable approach to precious metal use – evidencing what’s possible with a bold, circular vision.

Of course, The Royal Mint’s sustainability strategy goes the full extent too. In addition to employing groundbreaking technologies at its facility, the company has an all-encompassing energy commitment that follows suit. Up to 70% of electricity generated on site comes from renewable sources – including solar, wind, and heat power.

A bold new era of innovation

As electronic waste mounts at an unprecedented rate, The Royal Mint has set out to completely transform the e-waste landscape, not only rethinking how we handle WEEE disposal, but leading the way with an industry-first facility that is challenging what’s possible in sustainable precious metal production. The company remains committed to reclaiming value from what was once discarded, reducing dependence on mined materials, and closing the loop on a circular economy.

In embracing this vision, The Royal Mint has proven that true innovation doesn’t always come from the newest player – sometimes, it comes from those bold enough to redefine their legacy and reshape industries for the better.

Watch The Royal Mint’s process in action, in its official behind-the-scenes video.

Images available for download (may be reprinted for press purposes free of charge, picture credits: UNTHA shredding technology GmbH) https://untha.canto.de/b/SSJ4L

Image 1: The Royal Mint relies on three UNTHA RS30 to shred printed circuit boards and prepare them for the subsequent process steps

Image 2: UNTHA 4-shaft shredders and innovative processes help to recover valuable materials from electrical and electronic scrap

Image 3: The Royal Mint recycles up to 450 kg of gold every year and returns it to the material cycle