Reduced wear costs with increased service life

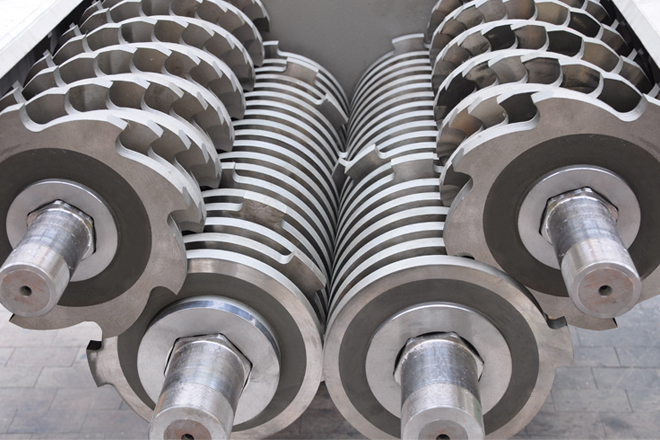

The rotor will be “refined” by our specially trained service engineers using high-quality wear protection, so that a long operating life can be guaranteed with the best possible throughput and return! This finishing using highly wear-resistant filler metals has proven itself best during on-going wear and exposure to blows, and increases the lifespan of the rotor many times over.

What benefits can you expect?

The wear of the cutting system is significantly reduced, thanks to the application of a premium-grade wear layer.

Maintenance intervals are extended thanks to increased availability.

You may also decide in favour of the hard surfacing of your rotor in retrospect. We will complete the task directly at your premises.

You would like to receive more information on our UNTHA services, get in touch with our service experts or book this service directly? Then you have come to the right place!

Everything from a single source

With UNTHA Lifetime Support, we provide you with support throughout the entire product life cycle and offer you comprehensive service products for maximum machine availability. Be it regular maintenance work, providing original spare parts and wearing parts or our individual carefree packages, we ensure that UNTHA machines are ready for use at all times and do what they were built for – namely reliable shredding.