Sustainable reconditioning reduces wear costs by 50 percent

The more demanding the material to be shredded, the faster wear becomes visible on the cutting unit. The consequences are declining throughput, decreasing quality of the output material and an increase in power consumption. All this is reflected in increased wear and operating costs.

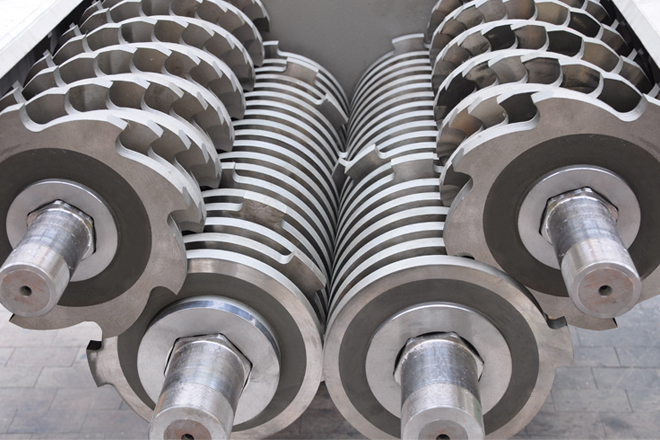

The cutting discs of the RS shredders can be professionally reconditioned at the UNTHA Service Competence Center. This saves you up to 50 percent of the costs compared to a new cutting unit. Our experts will be happy to advise you on the weld-on service and other measures to reduce costs.

What benefits can you expect?

Welding on the cutting unit restores it to its original dimensions and maintains the efficiency of the shredder.

With this service, we ensure maximum machine availability: Individual service intervals are planned in advance - for maximum flexibility in your processes.

The welding of the cutting discs can be repeated several times, only then will a new cutting unit be necessary. This saves you up to 50 percent in wear costs.

Our service experts accompany you throughout the entire product life cycle and advise you personally on suitable services and your individual savings potential.

You would like to receive more information on our UNTHA services, get in touch with our service experts or book this service directly? Then you have come to the right place!

Everything from a single source

With UNTHA Lifetime Support, we provide you with support throughout the entire product life cycle and offer you comprehensive service products for maximum machine availability. Be it regular maintenance work, providing original spare parts and wearing parts or our individual carefree packages, we ensure that UNTHA machines are ready for use at all times and do what they were built for – namely reliable shredding.