Products

Four-shaft shredders for universal use recycling applications

Rugged and compact machine construction

High availability and process stability

High resistance to foreign objects

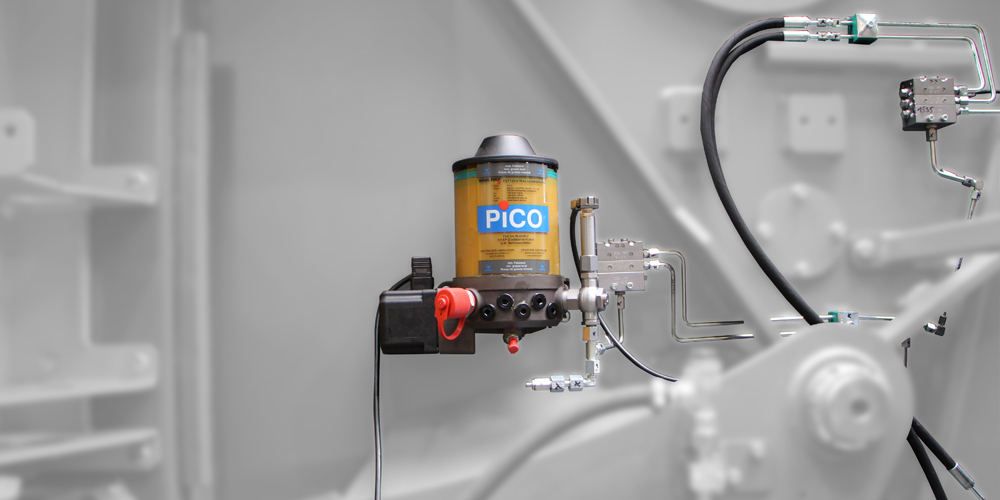

Low maintenance

Rated capacity: 11 / 15 / 22 kW

Feed opening: 450 x 600 mm

Fraction sizes (based on the screen): 15 - 40 mm

Rated capacity: 30 / 37 / 44 kW

Feed opening: 750 / 1.000 x 700 mm

Fraction sizes (based on the screen): 15 - 40 mm

UNTHA is the pioneer of 4-shaft shredding technology and has been contributing to the economical and ecological utilisation of many different types of ‘waste’ materials, for over 50 years. But with this rich heritage comes continued innovation – engineering advancements that never stop. Working closely with customers to gather insights from our many global markets, UNTHA’s R&D team consistently introduces progressive performance features that break new boundaries.

The result: more strength, more versatility, more uptime, more efficiencies, more potential.

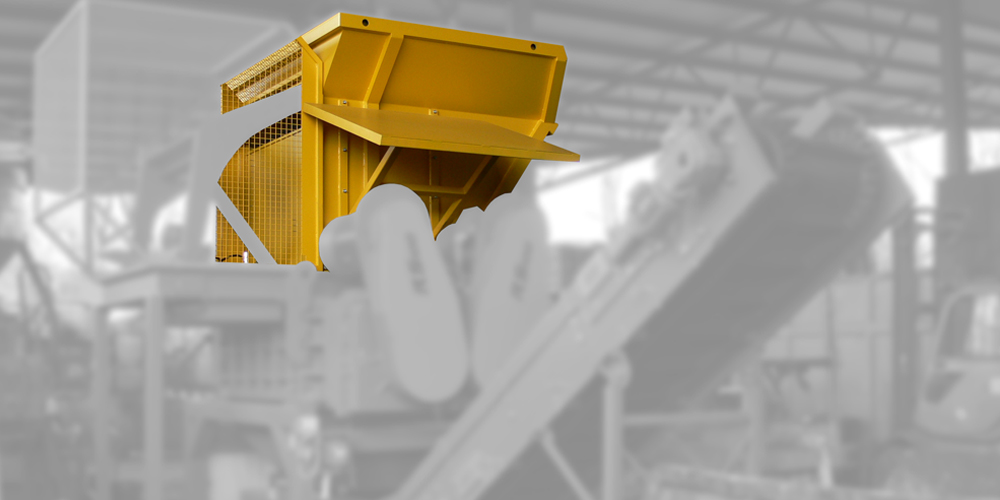

The RS class shredders are characterised in particular by their high availability and process stability. In addition, they are functional in design and uniquely productive. A special advantage of the four-shaft shredder is the high quality of the output material, which is achieved due to the efficient material disintegration during the shredding process. The optimised piece sizes and homogeneity of the shredded material are ideal for downstream sorting processes and the extraction of valuable resources.

The interchangeable perforated strainer permits the definition of granulate sizes depending on the application case. In general, each RS30 and RS40 shredder can be tailored to requirements, and is available either as a stand-alone solution or as a comprehensive solution.

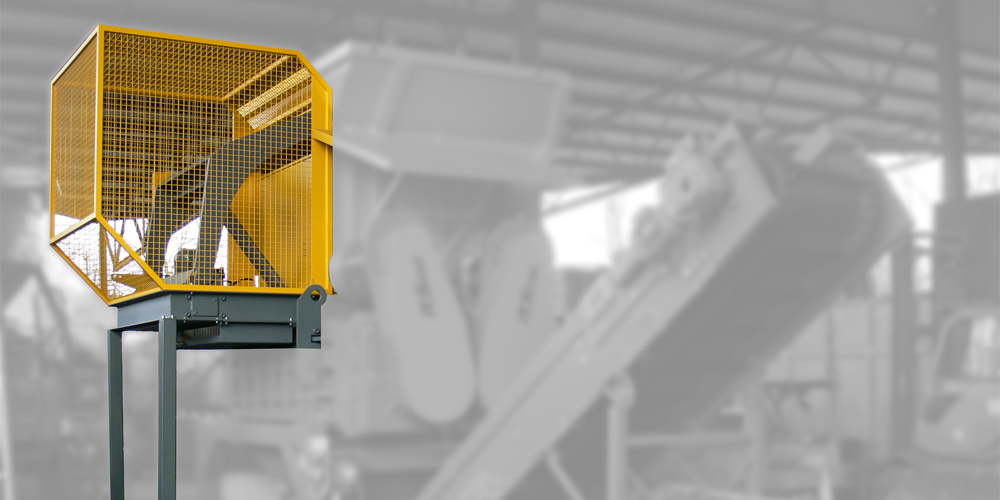

Other advantages of the compact shredding machines: The low-speed four-shaft shredders are resistant to extraneous objects, and very low maintenance. Thanks to the pull-in mechanism, the machines do not need a hydraulic pusher system, which further reduces the need for maintenance. The low cutting shaft speed ensures low noise and dust pollution.

Over and above this, the RS class shredders comply with high safety standards, which is of particular importance in the field of product destruction or the destruction of files and data.

Overall, the types RS30 and RS40 are highly flexible and can be used in different recycling applications such as files, dashboards, automotive interior panels, bank notes, data, hard drives, films, plastic packaging, leather, metal chips, paper, plastic bottles, production waste, packaging materials and much more.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

Depending on your requirements, we offer custom-made accessories for this shredder.

We are also happy to provide infeed and discharge conveyor belts. These will be optimally adapted to the on-site conditions and the desired throughput performance of the industrial shredder.