References

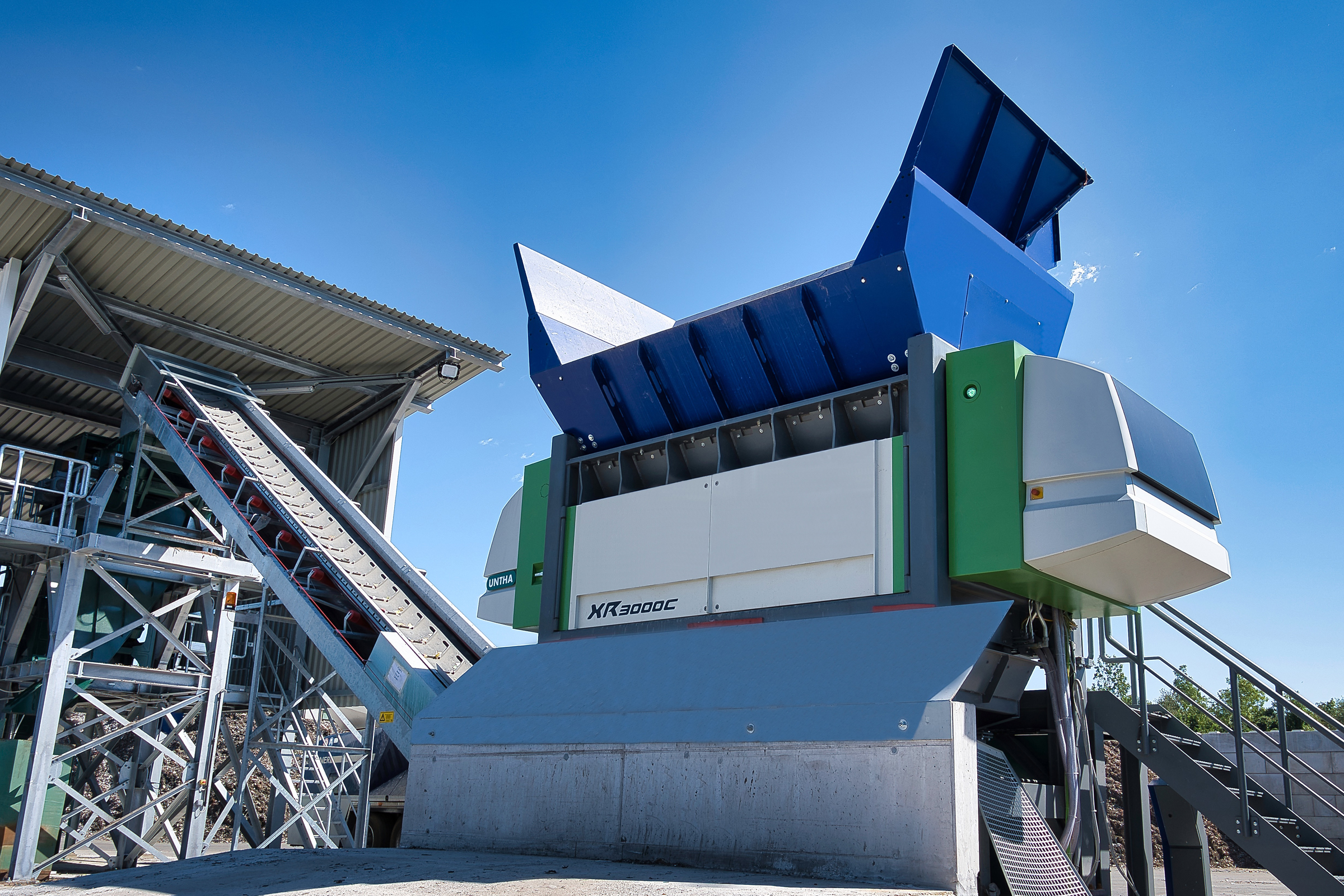

In the XR3000C shredder by UNTHA, Metran Aufbereitungsges. m. b. H. based in Lower Austria has found the perfect solution for the single-phase shredding of rigid plastics, thanks to the optimised breakdown of the composite materials for further sorting.

Metran Aufbereitungsges. m.bh.H. based in Kematen an der Ybbs/Lower Austria, focuses on the material recycling of industrial metals such as aluminium, zinc, copper and stainless steel as well as high-grade plastics, all from waste. The family business has been in operation at its Kematen site since 1984 and employs a staff of 45. It is part of the Müller-Guttenbrunn Group, which has 600 employees worldwide.

Among other things, Metran specialises in the processing of rigid plastics, a fairly new waste collection category. The particular challenge that Metran had to face was the single-phase shredding of rigid plastics that are bonded with iron and metals. With its iron handlebar

and axle, the Bobby Car is the perfect example for such a structure and has become something of a mascot for Metran. Ski boots, children’s car seats and garden furniture are other classic items in the collection of rigid plastics.

Metran receives these items from the municipal waste collection, shreds them in a single step and separates iron and metal using magnets and separators for non-ferrous metals. The company was on the lookout for a suitable situation to meet its single-phase shredding needs. The cut plastics are placed on the downstream separators and are sorted by the plastics arm of the company, MGG Polymers, into groups of identical materials such as PP, PE, PES, ABS and even PC or PC ABS, using extrusions systems. These fulfil the same criteria as new plastics and may be recycled indefinitely.

A stationary version of the new XR3000C has been in operation in Kematen since July 2020. Metran was able to test the XR unit on site, using the rigid plastics parts collected by the local council. The company quickly came to realise that the unit was exactly what they had

been looking for and that it delivers the cut required to obtain a two-dimensional output sized 5cm or smaller for further processing. Experience has since shown that the UNTHA shredder is also ideal for other material flows, for instance for breaking down more complex copper compounds.

The XR shredder by UNTHA constitutes the perfect solution for shredding rigid plastics. We are able to break down the material compound, separate iron and metal from plastics and prepare them for further sorting. The machine is expensive, but well worth it.

Ing. Gunther Panowitz

Managing Director

With the XR3000C and its competence when it comes to single-phase shredding, Metran has found the perfect shredder for this specific application. The company is particularly impressed with the compatibility of the blade blocks, the rotor and the stator with the iron and metal parts that are attached to the plastic components, and with the geometry of the shredded parts.

Other benefits for Metran are the low electricity consumption, straightforward maintenance and high throughputs of up to 10 tonnes per hour. The operator describes the characteristics of the XR3000C as robust, reliable and durable. Thanks to the sophisticated drive system, high throughputs are possible while using less electricity at the same time.