References

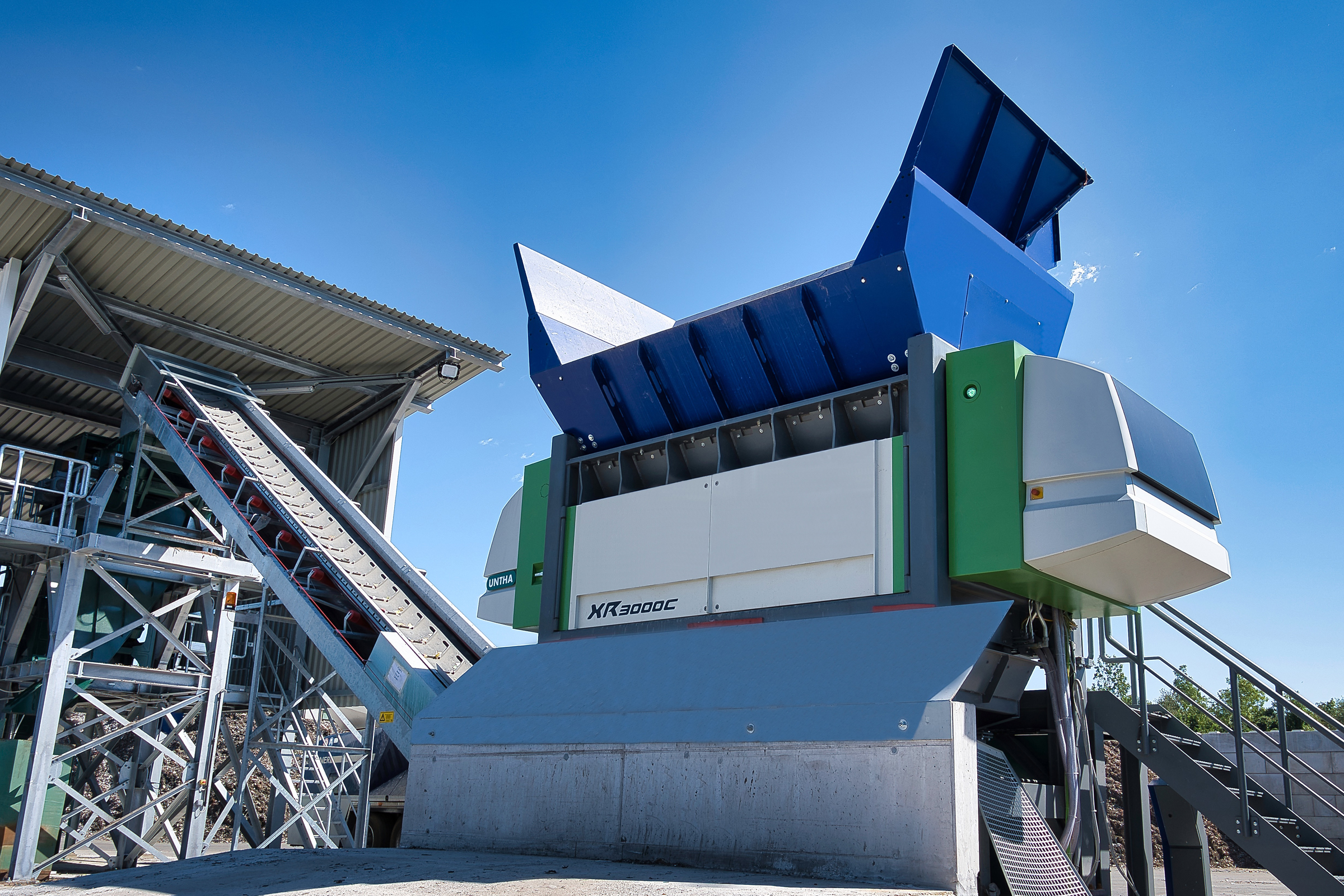

Korn Recycling relies on UNTHA’s solution-orientated XR3000C mobile-e for the recycling of residual wood and tyres. The decisive criteria for the recycling specialists were these: Electric

drive, mobility, cutting system, low maintenance, energy efficiency and a high throughput.

Korn Recycling operates one of the world’s most advanced commercial waste sorting and alternative fuel processing plants in Albstadt/Baden-Württemberg, Germany. The core competence of Korn Recycling is the recycling of waste from industrial, commercial and trading companies as well as communal bulk waste. The focus lies very much on innovative approaches towards the recycling and utilisation of waste.

Since 2002, the company has been producing high-quality alternative fuels for energy production in power plants. Alexander Korn is the second generation to head this 40-year-old, medium-sized family enterprise and employs more than 180 people at five different locations across three districts. With the logistics services offered by Korn Rekotrans, headed by Markus Korn, the company has a second string to its bow.

With the growing range of materials to be processed, the recycling industry is faced with increasingly stringent requirements. Korn Recycling was looking for an alternative to its old diesel-powered plant for the Albstadt site and had clearly defined criteria for its new shredding solution: Electric drive, mobility, cutting system, low maintenance, energy efficiency and a high throughput.

Korn Recycling invested in a XR3000C mobil-e. The shredder is mostly used for residual wood of varying classifications. At the Albstadt site, classes A1 to A3 are shredded to fraction sizes of 50 to 100mm. The XR3000C mobil-e can deal with 15 to 25 tonnes per hour, with the output going partly into thermal, partly into material recovery.

As the machines are highly flexible, they are also used for shredding tyres, with a throughput of around 6 tonnes per hour. The shredded material is then used as an energy source by a cement plant in the region. The XR3000C mobil-e also processes commercial waste or material flows, for a final product that is supplied to regional power stations.

We get a lot of visits from colleagues and partners who talk to us about shredding solutions, sorting technology, machines and plants, and I always recommend our UNTHA product. And praise from the mouth of a Swabian is high praise indeed!

Alexander Korn

Managing Director

The decision in favour of the UNTHA XR class shredder was preceded by a range of tests. Trial runs with different materials were completed, with the XR3000C mobil-e exceeding all expectations and leaving everyone impressed after the test run. UNTHA’s commitment to service and maintenance also played a big part in the purchasing decision.