Regens Wagner workshops in Dillingen work with the UNTHA RS40 shredder sourced from UNTHA Deutschland

The goal of the Regens Wagner foundation is to assist people with disabilities and provide them with a meaningful occupation. The Regens Wagner workshops in Dillingen an der Donau offer 25 different work areas, including one section for document destruction. Roughly 220 tonnes of documents are destroyed here every year using an RS40 shredder from UNTHA Deutschland, in compliance with the GDPR.

Sister Maria Theresia Haselmayer and Father Johann Evangelist Wagner, head of the local seminary, founded the Regens Wagner foundation back in 1847. Today, the foundation operates more than 50 branches across southern Germany and Hungary. The concept of the Regens Wagner workshops was born from the principle “Whoever gives us work, gives us bread.” The goal is to open up new perspectives for people with disabilities and to find meaningful tasks for them to do, in line with their skills and interests. This creates a structure for their day and a safe framework in which they can meet other people and further develop their skills.

Multi-faceted work areas at Regens Wagner Dillingen

“People are at the centre of everything we do at the Regens Wagner workshops, and we try to find the right task for everyone, depending on their skills, likes and dislikes. In many cases, we create new responsibilities and adapt them to the individual”, says Uwe Runnwerth, Director of the Regens Wagner workshops in Dillingen. The Dillingen site consists of 25 work areas, including laundry, landscape conservation section, metalworking section, printing shop, bookshop, and document destruction section. The documents that are shredded there come from businesses, medical practices, banks, law firms and municipal institutions. In 2014, the section became certified as a specialist enterprise for the destruction of documents and data carriers according to DIN-66399. Customers may thus rest assured that their documents are destroyed reliably and irretrievably, in line with the GDPR.

The document shredding section is housed in a dedicated building, which means that they are processed in a safe area, divided into a preparation and a shredding room. The focus of document shredding in Dillingen is to give people with disabilities a meaningful occupation. The documents that arrive at the site are prepared by twelve employees, supported by two educational supervisor. The preparation process was split into several work steps that reflect the talents and opportunities of the employees: removing the files from containers, separating the individual materials (paper, plastic, metal parts), dismantling the file folders, checking the paper, placing it on the conveyor belt. The UNTHA RS40 is fed purely paper. The resulting paper shreds are placed in a container, which is later collected by a recycling company, where it is compressed into bales. These bales are taken to paper mills and used for making new paper. The process preserves resources and contributes towards greater sustainability.

Certified document destruction with the UNTHA RS40

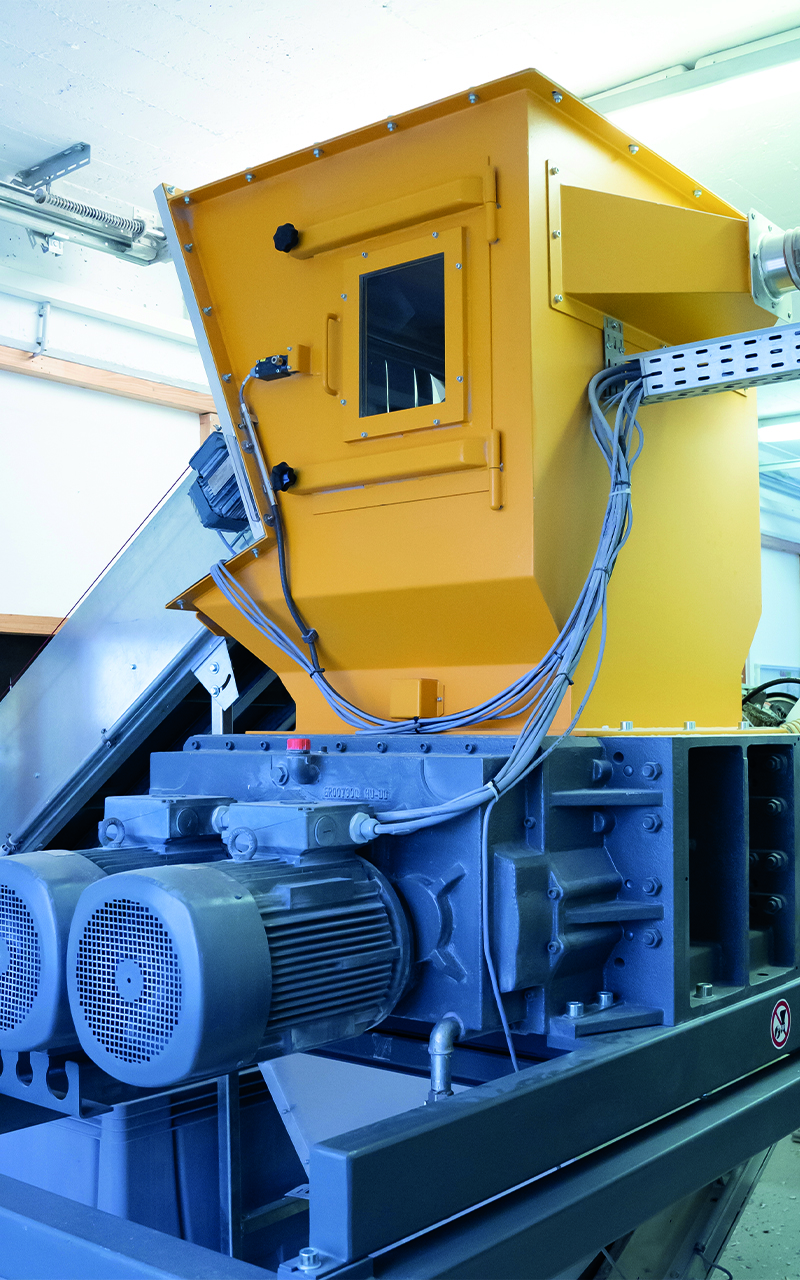

The Regens Wagner workshops in Dillingen had clearly defined expectations for their new shredder: a throughput of at least 300 kg/hour, shredding according to security level P3, resistance towards non-shreddables, and a high level of availability. In addition, the new shredder would have to be integrated into the existing premises and conveyor technology. “UNTHA convinced us right from the start. The staff of UNTHA Deutschland provided competent advice and recommended a shredder that could be integrated perfectly into the existing periphery”, explains Thomas Haselmeier, head of document destruction in the Regens Wagner workshops in Dillingen.

The UNTHA RS40 stands out for its high availability and process safety. It is a four-shaft shredder that works efficiently and evenly, with barely any noise and dust production. With this shredder, paper may be shredded in line with safety standards P1 to P4. “The UNTHA RS40 fulfils all our expectations. It runs failure-free, has a high throughput, and produces evenly sized particles. We are absolutely satisfied and happy to recommend both UNTHA and the RS40 to others", says Thomas Haselmeier.

Vocational rehabilitation trade fair in Nuremberg

Regens Wagner first noticed UNTHA at the Werkstättenmesse, the vocational rehabilitation trade fair, in Nuremberg. This year, the trade fair will take place from 19 until 22 April. The UNTHA Deutschland team will attend in hall 12 / stand 230, answering questions on document and data destruction, the UNTHA shredders and their areas of application.

About Regens Wagner

Regens Wagner foundation was founded in the mid-19th century by the head of the Dillingen seminary, Johann Evangelist Wagner, in cooperation with the Mother Superior of the Dillingen Franciscan order, Sister Maria Theresia Haselmayr. Today, Regens Wagner operates 14 regional centres at more than 50 sites in Bavaria as well as one site in Hungary, offering people with disabilities a range of services, educational and training opportunities, work/occupation, assisted living facilities, advisory services, mobile and at-home care services. At present, more than 9,300 people – children, young people, adults and senior citizens – with a range of disabilities are cared for and supported by the foundation and its 7,500 employees. The focus for the Regens Wagner foundation and all its employees is on professional competence and quality, humanity and spirituality put into practice. Every individual is recognised as a person in their own right and as a valuable member of society.

Images (reproduction for press purposes free of charge; image credit: UNTHA shredding technology GmbH)

Fig. 1: (left to right) Thomas Haselmeier, head of the document destruction section at Regens Wagner, and Uwe Runnwerth, head of the Regens Wagner workshops in Dillingen an der Donau.

Fig. 2 & 3: The UNTHA RS40 in Dillingen shreds roughly 220 tonnes of files and documents per year.

Fig. 4: The UNTHA RS40 in use at Regens Wagner Dillingen shreds files down to a particle size of 320 mm², in line with security level P3.