References

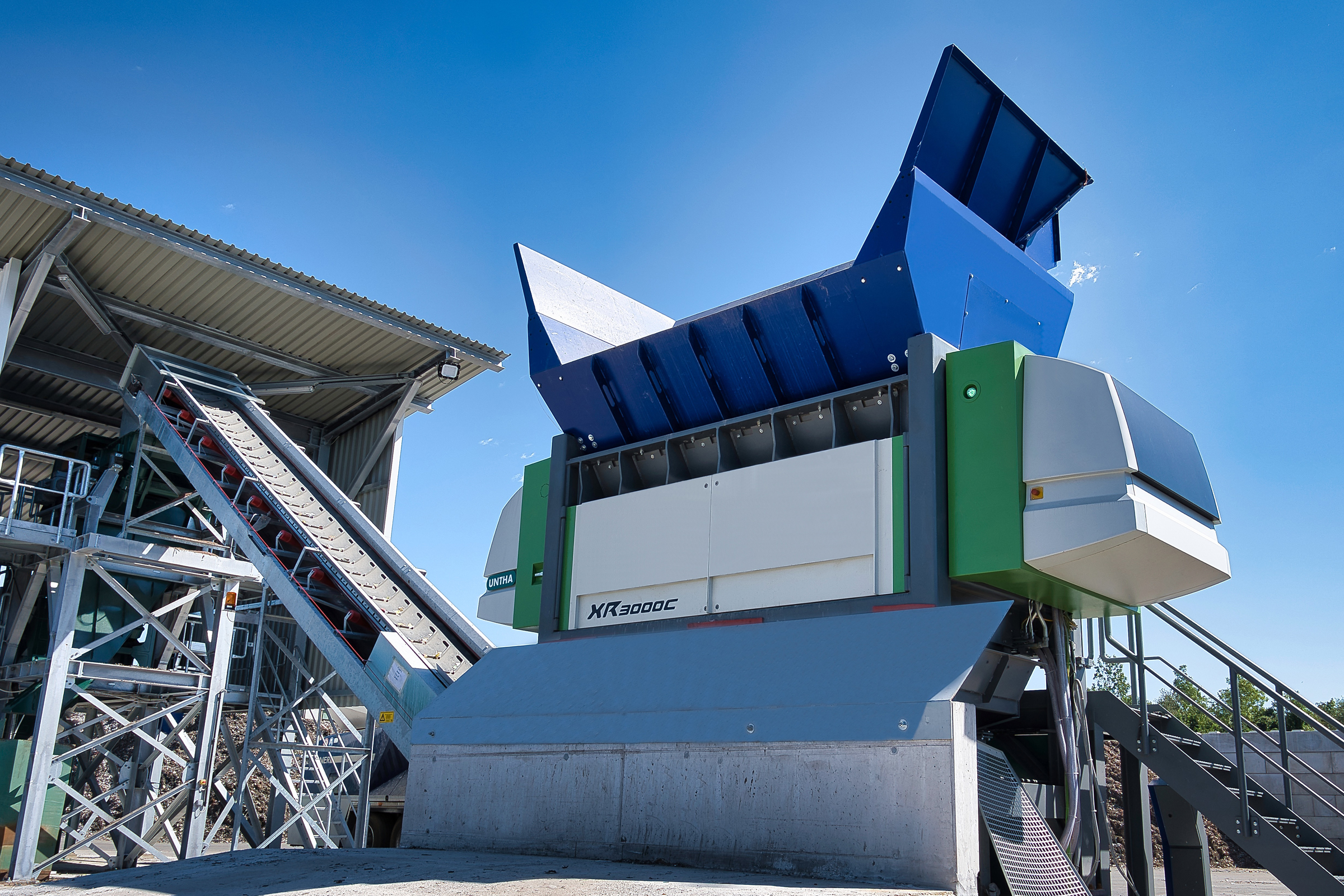

Since 1988 FCC Austria has been processing and disposing of waste from commercial and industrial companies as well as from municipalities and private individuals. And for around 20 years, the company has relied on shredders from UNTHA. It chose the UNTHA ZR2400 2-shaft shredder – it is particularly robust and saves up to 90,000 euros a year in electricity costs.

FCC Austria Abfall Service AG provides comprehensive, integrated waste management solutions for municipalities, industrial sites, commercial enterprises and private households. The company is part of the Spanish FCC group. Which is the largest provider of environmental services, with a focus on waste management in Central and South-Eastern Europe. The central location in Himberg near Vienna employs roughly 200 people.

65,000 tonnes of waste per year are handled by the company, largely for thermal processing in a combustion plant. The reason for the purchase was the need to replace an existing single-shaft shredder from a competitor. Due to its limited throughput and high susceptibility towards non-shreddables, the unit no longer fulfilled the site’s everyday requirements. The specifications for the new shredder were extremely detailed: The shredders run continuously and process a range of difficult materials with a high non-shreddable content. The company was looking for an energy-efficient, 2-shaft-shredder, preferable with an electromechanical drive, a throughput of 50 tonnes per hour, a high level of resilience against non-shreddables, and a low maintenance profile.

FCC Austria eventually opted for the UNTHA ZR2400H, with its emphasis on cutting power, throughput, susceptibility towards non-shreddables, reactivation in case of non-shreddable input, and low maintenance requirements. The energy efficiency of the shredder was deemed particularly impressive, resulting from the water-cooled synchronous motor (UNTHA Eco Power Drive), and yielding a power saving of up to 100 kWh per operating hour compared to the competition. The machine runs approx. 3,600 hours per year, in two-shift operation. With the price of electricity at an average of 25 cents/kWh, the annual saving amounts to an impressive 90,000 Euro. The option of removing non-shreddables via doors on the feed-in side as well as the back of the unit and the easy access for service activities were also decisive factors. Another benefit is the low height of the unit, suitable for feed-in using a wheel loader.

Our shredders run continuously and process difficult materials with a high non-shreddable content. We therefore expect a lot of our shredders. The UNTHA ZR2400H fulfils our requirement profile to the letter and applies state-of-the-art technology.

Franz Aschenbrenner

Head of Operations

Prior to the purchasing decision, four models by different manufacturers were tested over a period of several weeks. At the end of this trial phase, there was a clear winner: “The UNTHA ZR2400H fulfils our requirement profile to the letter and represents the state-of-the-art. The service aspect has also convinced us: From the trial phase to planning and handling and all the way to commissioning, there were no issues whatsoever. FCC Austria has been working with UNTHA pre-shredders for 20 years. The purchase of the ZR2400H in July 2022 marks the arrival of the third generation of machines by the Austrian premium manufacturer at FCC Austria.