References

For the recycling of materials, a homogeneous output material is essential. That's why Foucault Recyclage chose an XR-class shredder: energy-efficient, insensitive to contaminants, and versatile. This allows the company to expand its range of services and adapt them to the requirements of different customers, such as those from the wood energy industry or panel manufacturers.

Foucault Recyclage was founded in 1900 and has been a 100 percent independent waste collection and processing company for three generations. At its site in Machecoul, France, the company processes around 20,000 tons of waste per year from construction and industrial companies, municipalities, and private individuals. This includes metals, wastepaper and cardboard, wood, plastics, cables, and glass. Foucault's goal is to process as much of this waste as possible for recycling, thus contributing to a sustainable circular economy. For these efforts, Foucault was awarded the LUCIE 26000 CSR label.

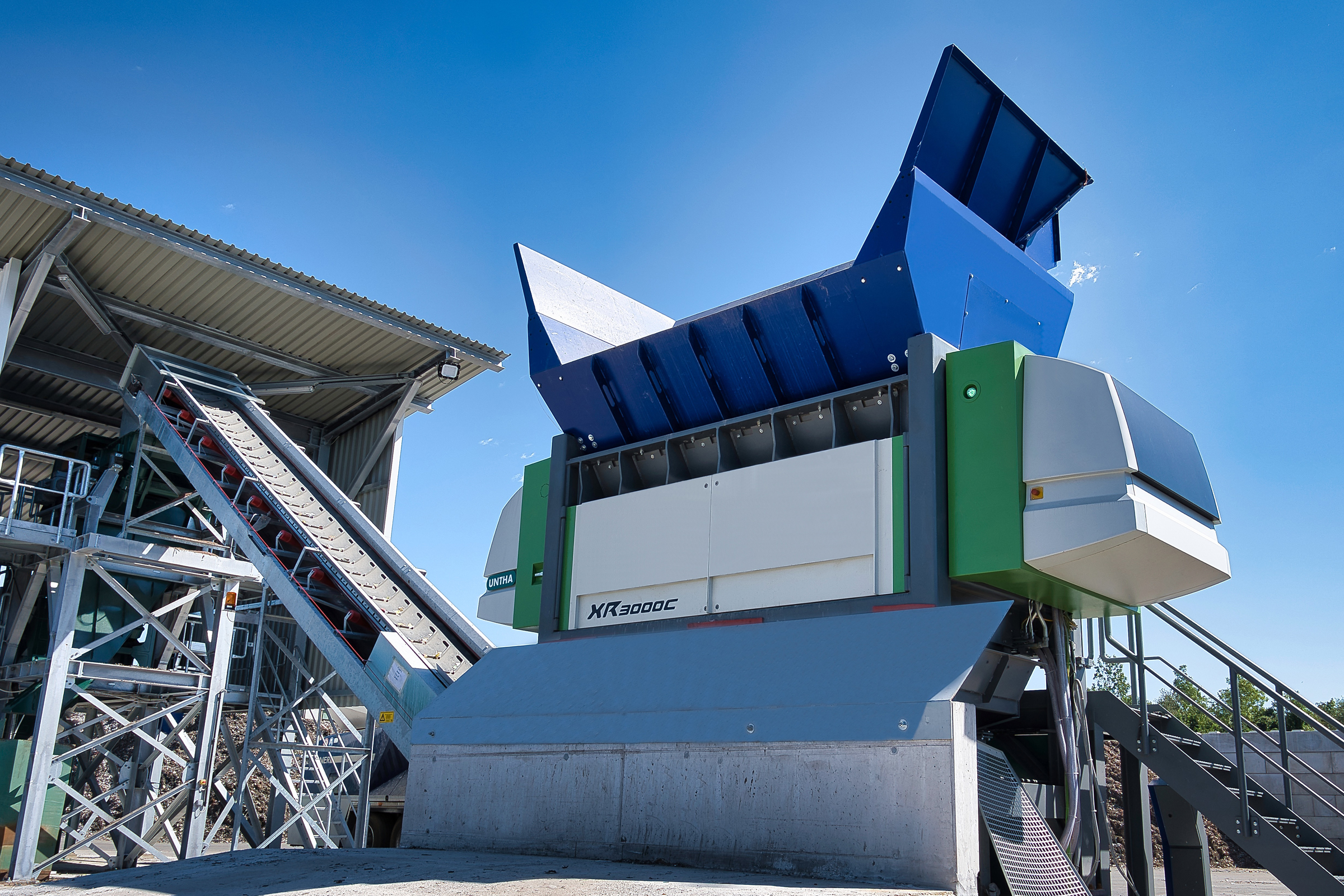

A shredder was sought for processing different materials, such as scrap wood, cable, and aluminum. One of the most important criteria was the quality of the starting material: homogeneous grain size and free of impurities. In the search for a shredder that meets these criteria and is versatile, machines from different suppliers were tested. PROXIREC – representative of UNTHA in France –finally presented the XR3000C mobil-e to the company.

The XR3000C mobil-e impressed above all with its diverse areas of application, electric crawler chassis and energy efficiency. Thanks to the UNTHA Eco Power Drive, the XR is up to 75 percent more economical than comparable diesel-powered shredders. The C-cutting system (cutter) and the replaceable perforated screens ensure homogeneous output material. Depending on the perforated screen, fraction sizes between 25 and 300 mm can be achieved. The shredded granulate is very uniform and is therefore ideally suited for further material recycling in recycling companies. The XR is a slow-running 1-shaft shredder that is particularly resistant to disruptive materials and requires little maintenance. The knives of the cutting unit can be easily rotated and can thus be used four times.

We chose the UNTHA XR3000C mobil-e because we place particularly high value on the quality of the output material (homogeneous, free of impurities). This shredder is versatile, mobile, powerful and energy-efficient at the same time.

Sebastian Foucault

Managing Director

At Foucault Recyclage, the quality of the shredded feedstock played a major role: The demands of the recycling companies that process the material are very high. In addition, different materials are to be processed with a single shredder. The XR3000C mobil-e from UNTHA meets all these criteria. This shredder is also very energy-efficient, versatile (by inserting different perforated screens and adjusting settings) and easy to maintain. UNTHA representative PROXIREC and the contact persons from UNTHA were also convincing with their consulting competence and service.