References

Zuser Ressourcenmanagement has been relying on UNTHA shredders for years. These include the XR3000RC mobil-e and XR3000C mobil-e models. These can be used flexibly thanks to the different perforated screens and screen bars and the electric crawler chassis. The company uses them to process various types of private, municipal, and commercial waste into refuse derived fuel (RDF) and substitute raw materials.

Zuser Ressourcenmanagement GmbH produces over 100,000 tons of refuse derived fuel with a high energy content and degree of purity every year. Commercial waste, lightweight packaging, used tires and rubber, among other things, are processed. Another focus is material recycling. The company sorts high-quality plastics such as PET and films as well as ferrous and non-ferrous metals from waste and ensures that they are returned to the material cycle.

At its site in Peggau, Styria, Zuser produces high-calorific substitute fuels from commercial waste with a bulk density of 80 kg/m³. A new pre-shredder was needed for production line 1 – consisting of a shredder, conveyor belts and a sorting system.

Requirements:

Energy efficiency

Electric drive

Throughput: approx. 18 t/h

Homogeneous output material

Electric crawler-type undercarriage

The UNTHA XR3000RC mobil-e meets all requirements: It is a 1-shaft shredder with a particularly high throughput rate and an economical drive. The low-speed UNTHA Eco Power Drive – consisting of two water-cooled synchronous motors – consumes up to 75 percent less energy than comparable diesel-powered shredders. The RC cutting system (Ripper Cutter) with its unique tooth shape ensures that the material is optimally drawn in and shredded. Depending on the desired size of the starting material, sieve bars or different perforated screens can be used. Granulate sizes of 90–300 mm can be achieved. A magnetic separator above the discharge conveyor sorts out metals, which are then recycled. Thanks to the electrically crawler-type undercarriage, the shredder can also be used at other locations on the company premises, thus ensuring 100% system availability.

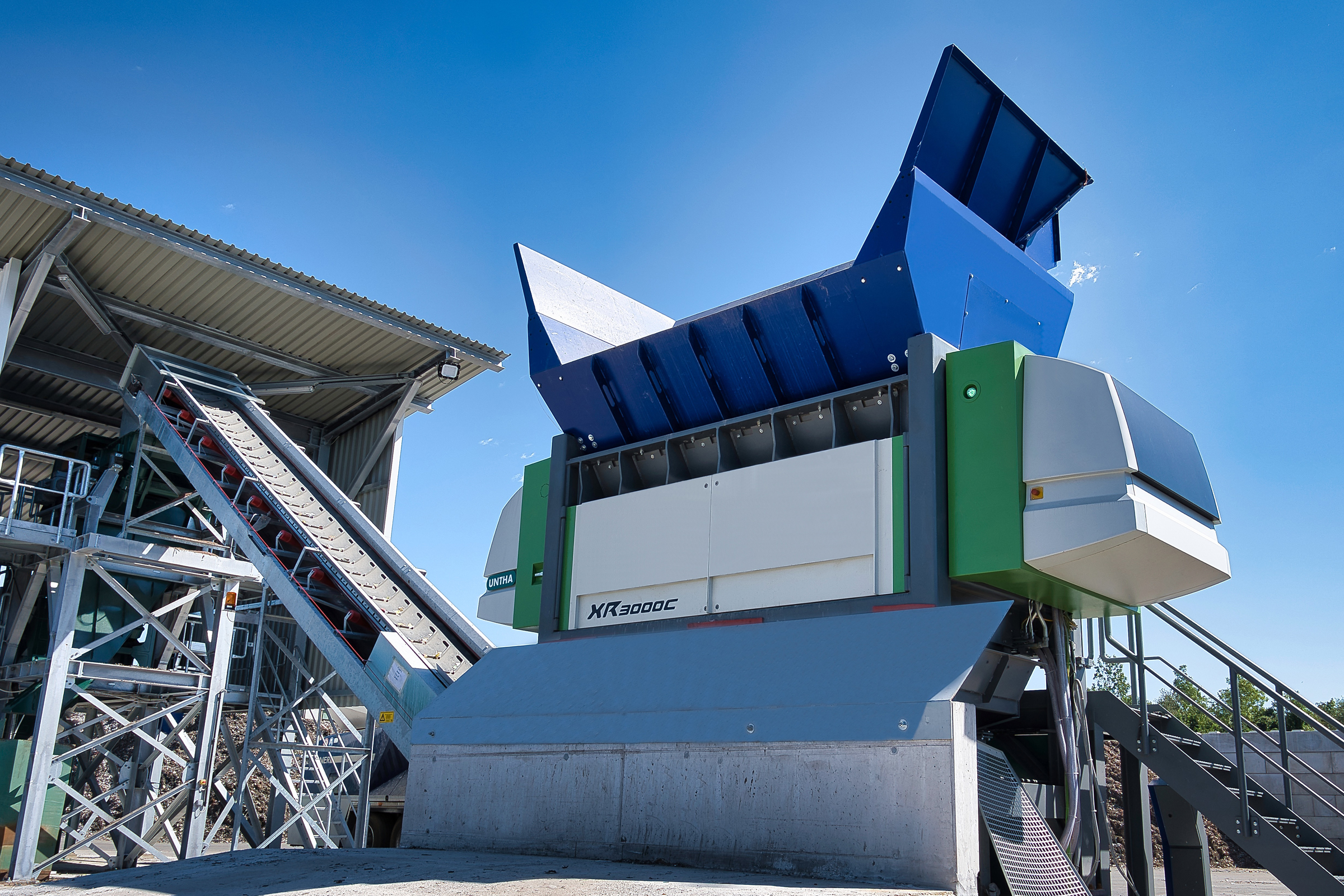

Zuser also uses a UNTHA XR3000 mobil-e with a C-cutter. It shreds around 10 t/h of tires and rubber waste to a granulate size of 16 mm. Metals are also sorted out here using a magnetic separator.

The UNTHA XR3000RC mobil-e and XR3000C mobil-e shredders are energy-efficient, ensure high throughput rates and a homogeneous output material. They can be used flexibly: thanks to different perforated screens and sieve bars, they are suitable for shredding various materials. The electric crawler drive allows the shredders to be moved to different locations and connected with just one plug.

André Riemer

Head of Processing Technology