Продукты

Малый компактный шредер для измельчения древесины в столярных и плотничных цехах

Небольшая занимаемая площадь

Усовершенствованная технология

Энергоэффективный принцип работы привода

Однородная щепа на выходе

Индивидуальные системные решения

Полная 3-годичная гарантия

WEEE / Electronic Waste

Specialities and hurdles

For the efficient shredding of electronic waste in your recycling plant, we offer you individual solutions and a perfect match for your recycling system. The size of the granulate is adjusted so that metals and non-metals can be separated and recycled in the best possible way.

Over 40 million tons of electrical and electronic scrap are generated worldwide every year - and the trend is growing rapidly! Recycling electronic devices is not only worthwhile for environmental reasons. This scrap usually contains many precious metals that are recovered in the recycling process. In order to ensure a high yield in recovery, only a small amount of fines should be produced during the shredding.

What is WEEE?

But within every piece of ‘redundant’ equipment lie a number of high-value component parts that – in line with the waste hierarchy – should be liberated, segregated and recycled. It doesn’t just make environmental sense – this methodology can yield impressive business revenue too.

The shredded and processed electronic scrap is divided into its various components by downstream separation technology in order to recover valuable materials. Our rotary shears are the first choice when careful processing of electronic scrap with little fines is required.

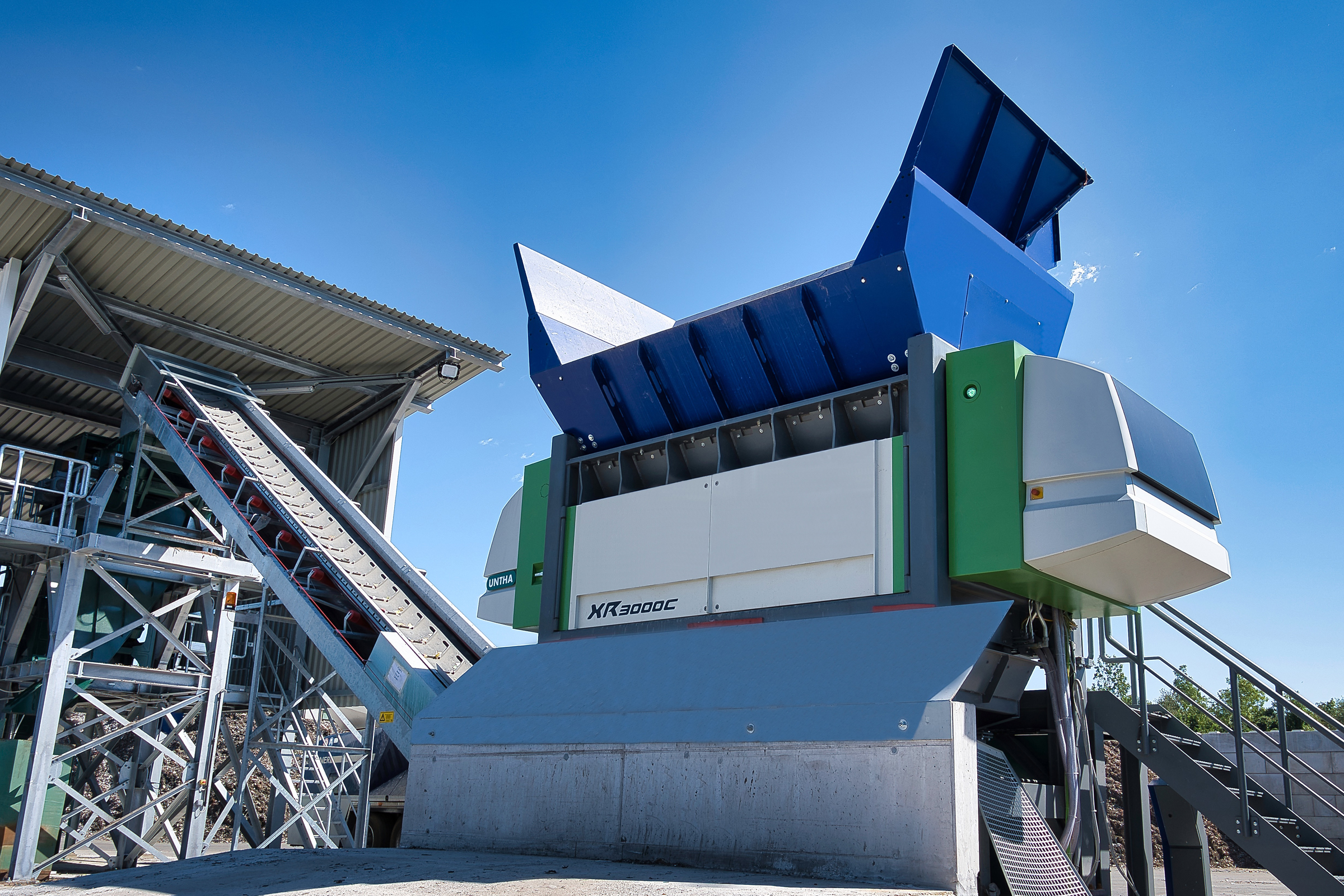

The product XR 3000 has surprised us in so many ways. One of them was the energy efficiency, but especially the wearout. These facts were decisive for us in the decision-making process for the certain company and the specific product. Thus, we are looking into a bright future together. The partnership with UNTHA is very important to us, whereby we have made another big order for additional shredders for our production system. We can totally recommend the company!

DI Dr. Paul Losbichler

CEO of Schaufler Metals

The new XR mobil-e represents a revolutionary machine concept in mobile waste shredding. The many advantages of the electromechanical drive are used without having to forego the advantages of a mobile machine. This guarantees you maximum economy and flexibility. In the following, you can find the hard facts in an overview:

The XR-Class is an extremely powerful shredder for substitute fuels, which is used either as a pre-shredder or as a single-stage processing system. It is very low-maintenance and easy to maintain and therefore enables you to have a very long service life. The XR-Class is a very economical and slow-running 1-shaft shredder and was specially developed for the coarse, medium and fine shredding of untreated household waste, industrial and commercial waste as well as for waste wood processing. The availability of spare parts for 48 hours and the option of remote maintenance ensure that your system runs smoothly!

Thanks to the innovative UNTHA Eco Drive electric drive, the energy costs are only around 75% compared to diesel-powered mobile machines.

The wear-free direct drive works without belts or shaft stubs and is therefore not susceptible to thermal failures.

A contaminant discharge system enables foreign bodies to be removed quickly and thus reduces the downtime of the shredding machine to a minimum.

The shredder can be flexibly maneuvered via radio remote control thanks to the integrated crawler chassis.

Video summary of the project

EN - Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua.

rat, sed diam voluptua.

rat, sed diam voluptua.rat, sed diam voluptua.

rat, sed diam voluptua.

What is the output in the end?

Our tried and tested and reliable 4-shaft technology is particularly suitable for processing rubber and rubber waste from production. These shredders have always impressed with their high performance and, thanks to their compact design, can be easily integrated into existing systems. This means that pre- and post-shredding can take place in just a single and therefore very economical step.

We got to know the brand UNTHA due to recommendations. We are sure to have taken the right decision. As a consequence, we can definitely recommend the XR 3000C. It has revolutionized our recycling output of waste material by up to 70 %, which we would habe never been able to accomplish with another partner or shredding solution.

André Rabeus

CEO, Otto-Rüdiger Schulze

For the protection of your personal data the connection to Youtube has been blocked.

Click the button to remove the blocking of Youtube.

Video of the project

Als Unternehmen sind wir authentisch und erwarten das ebenfalls von unseren BewerberInnen.