References

The goal of the Regens-Wagner foundation is to assist people with disabilities and provide them with a meaningful occupation. In the department for document destruction of the Regens-Wagner workshops in Dillingen an der Donau, roughly 220 tonnes of files per year are shredded in line with the provisions of the GDPR.

The Regens-Wagner foundation operates 12 regional centres in Bavaria and Hungary, offering people with disabilities a range of services such as educational and training opportunities, work and occupation, assisted living facilities and advisory services. At present, more than 9,200 people with disabilities are cared for and supported by the foundation and its 7,300 employees. The goal of the Regens-Wagner workshop in Dillingen is to assist people with disabilities and provide them with a meaningful occupation in line with their skills and interests. One of the 25 working areas is the department for document destruction.

The Dillingen sites processes approx. 220 tonnes of files from medical practices, municipal institutions, banks and law firms every year. The files contain highly sensitive data, making it imperative to destroy them in line with the GDPR. The Regens-Wagner workshop in Dillingen had clearly defined expectations for their new shredder: a throughput of at least 300 kg/hour, shredding according to security level P3 (particle size > 320 mm²), resistance towards non-shreddables, and a high level of availability. In addition, the new shredder would have to be integrated into the existing premises and conveyor technology.

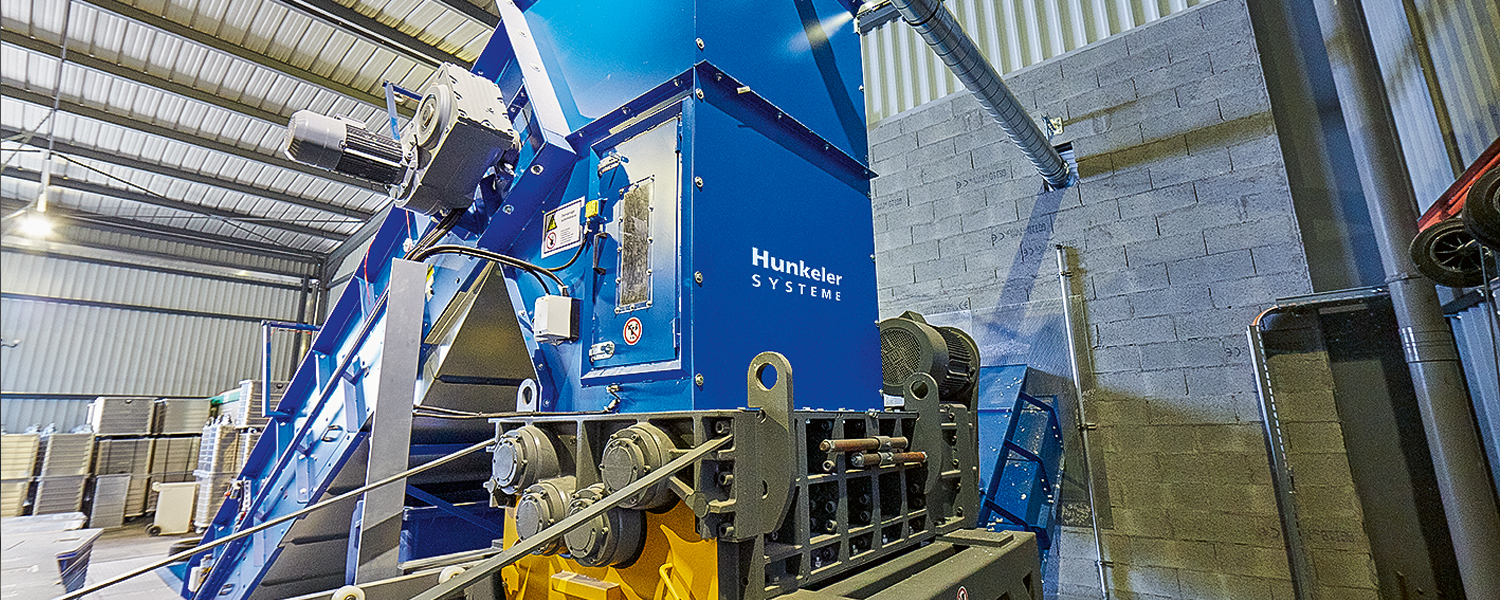

Regens-Wagner opted for the UNTHA RS40 with a 22-25 mm perforated screen. The shredder fulfils all the specifications and produces a homogeneous output. Thanks to the highly reliable shredding results, the department was certified as a specialist enterprise for the destruction of documents and data carriers according to DIN-66399 in 2014. This guarantees that files are destroyed in line with the provisions of the GDPR. The RS40 has a slow-running cutting system that keeps dust and heat to minimum, thus practically eliminating any fire risk.

Before the files are shredded, they are sorted and separated into the different recyclable materials: paper, plastic and metal. The paper documents are then taken to the shredder by a conveyor belt and shredded in line with security level P3. The shredded material is collected by a recycling company and compressed into bales. These bales are taken to paper mills and used for making new, high-grade paper.

The UNTHA RS40 fulfils all our expectations. It runs failure-free, has a high throughput, and produces evenly sized particles. We are absolutely satisfied and happy to recommend both UNTHA and the RS40 to others.

Thomas Haselmeier

Head of document destruction

Regens-Wagner first came across UNTHA at a trade fair. UNTHA suggested the RS40 during the consultation meetings, and the Regens-Wagner staff were able to see for themselves what the RS40 is capable of during a visit to Munich Airport, where they were shown a reference unit. UNTHA adapted the RS40 to the requirements of the workshop, with a bespoke undercarriage to connect the shredder to the existing conveyor system, a closed hopper to prevent dust formation, and by adjusting the shredder speed to the speed of the operators.