Secure Recycling scales up electronic waste shredding operations with duo of UNTHA shredders

Solon-based Secure Recycling scales up electronic waste shredding operations with duo of shredders. Secure Recycling, a specialist in electronics IT asset disposition services, first invested in an RS100 shredder from UNTHA America in 2020 to establish a reliable foundation for its recycling operations.

As the company grew, the need for increased processing capacity and efficiency has led to the addition of the ZR2400W and XR3000C Mobil-e shredders.

These state-of-the-art machines have not only enhanced throughput but ultimately replaced the RS100, optimizing Secure Recycling’s operations with superior performance, cost savings, and reduced downtime.

The ZR2400W preshredder has reduced the power required for shredding and enabled Secure Recycling to process larger and heavier materials – such as printers and stadium-sized LED panels – while the XR3000C shredder, thanks to its robust construction and superior ability to handle unshreddable objects without sustaining damage, has achieved approximately four times the throughput compared to the RS100, further enhancing efficiency and performance.

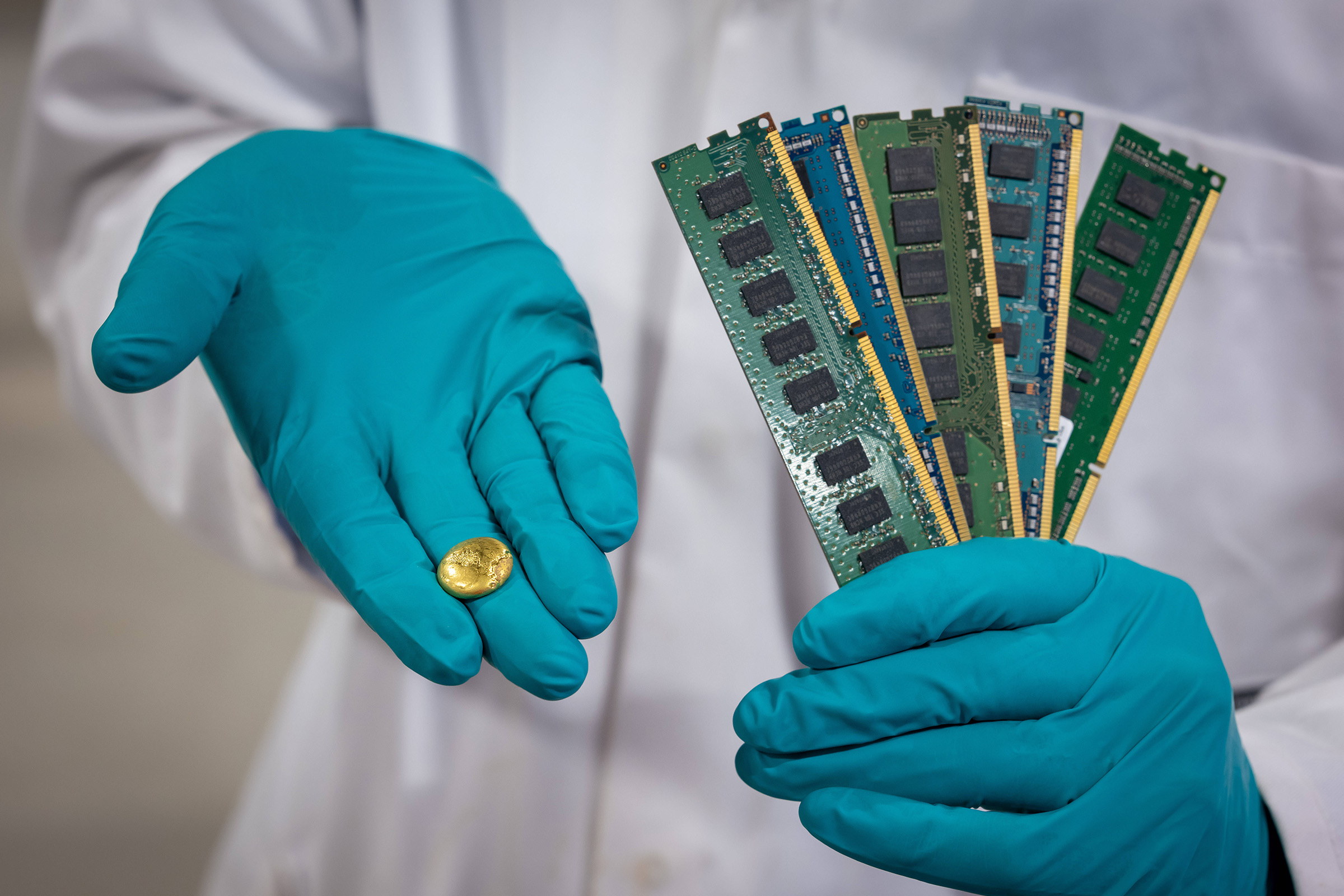

Secure Recycling processes a wide range of electronic waste, achieving throughput rates of up to seven metric tons per hour, depending on the material. The shredders consistently produce a 2-inch particle size, which is then further separated using cutting-edge technologies to maximize resource recovery.

“These machines are the backbone of our operations,” Mario Jurcic, president of Secure Recycling, explained. “Their robustness and ease of maintenance give our team the confidence to push boundaries and see what’s possible.”

This investment aligns with Secure Recycling’s long-term vision for growth and environmental responsibility. The shredders have dramatically reduced downtime – delivering the company’s lowest-ever operational interruptions since its inception. Additionally, the energy-efficient technology helps lower costs while promoting sustainability in the electronics recycling industry.

With these advanced shredders in place, Secure Recycling is poised to explore new market opportunities and continue its trajectory of steady growth. “Our journey is built on hard work and determination, and these shredders are a key ingredient in our recipe for success,” said Jurcic.

"Secure Recycling has been a fantastic partner for UNTHA America. The firm’s commitment to innovation and efficiency in e-waste recycling sets a high standard for the industry," said Charles Hildebrand, sales manager at UNTHA America. "This project showcases the power of our shredding technology in delivering reliable, cost-effective solutions for high-volume electronic scrap processing. We're proud to support Secure Recycling in its mission to advance sustainable IT asset disposition."

As a RIOS-certified recycler, Secure Recycling remains committed to providing secure and compliant IT asset disposition services to individuals, corporations, and government entities across the nation. The company’s latest investment ensures it will continue to lead the way in responsible electronics recycling for years to come.