About us

Welcome to the world of reliable shredding technology!

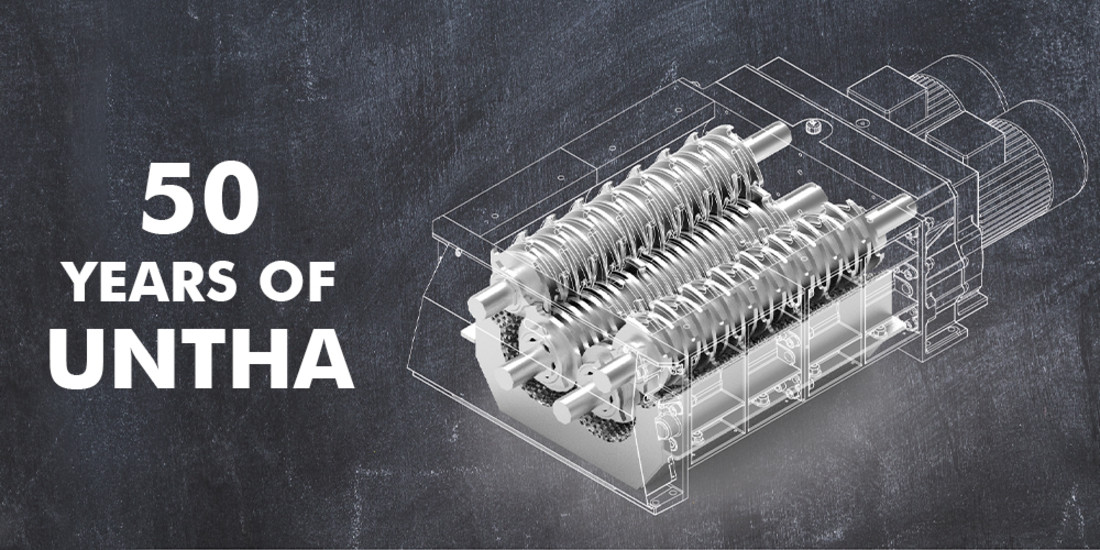

Since the company was founded in 1970, UNTHA has been fulfilling its promise to be "The reliable brand", meaning that we do everything we can to be more reliable than other providers.

This applies to all UNTHA products and services. For our customers, this means that choosing an UNTHA system was the best decision they could make.

The status quo

Quality "Made in Austria" - worldwide customers

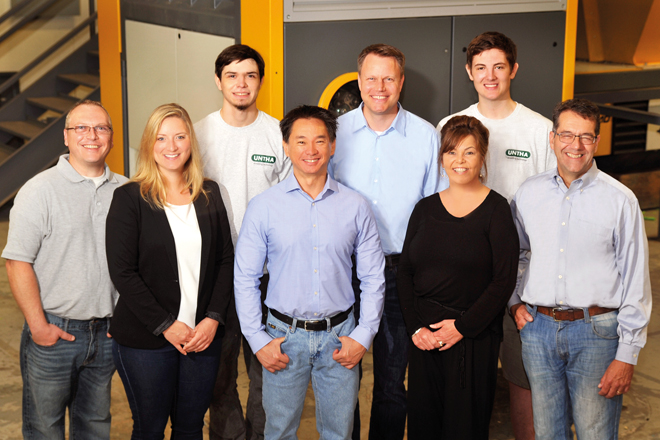

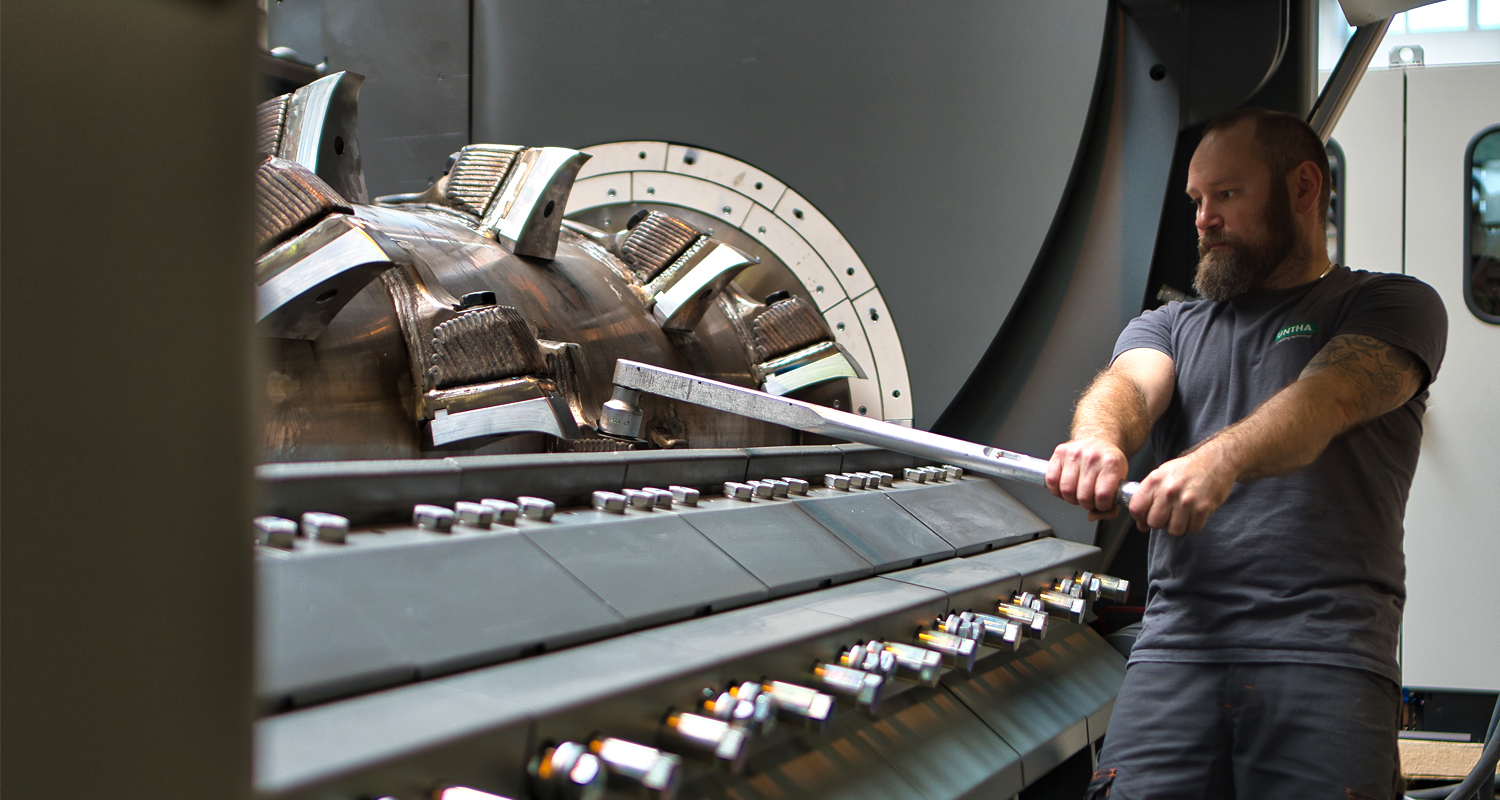

Today, UNTHA employs 500 people all over the world. All shredders are developed, manufactured and assembled at the Kuchl site. UNTHA shredders are used in a wide range of applications, from material recycling to the processing of residual and waste wood and the reprocessing of waste to produce alternative fuels.

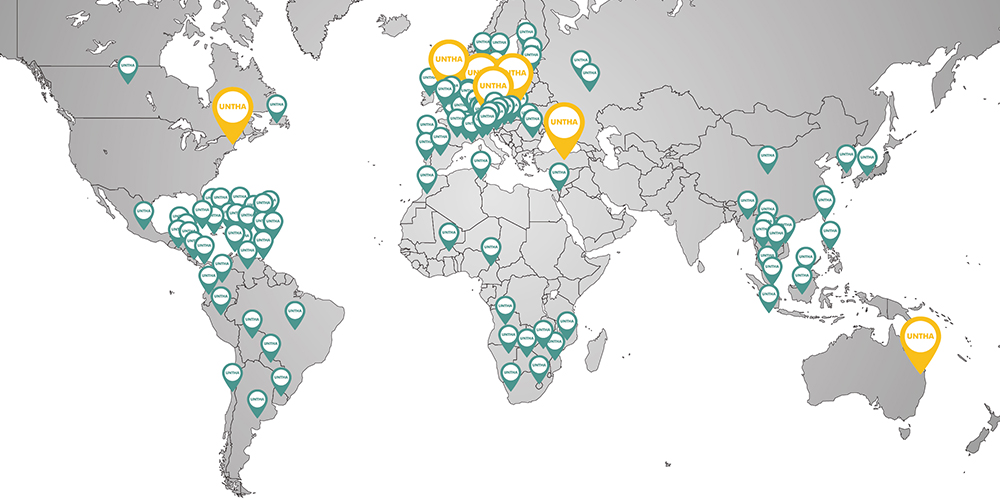

In this way, the company makes an important contribution towards the conservation of resources and the sustainable processing and reduction of waste. With subsidiaries in the US, Great Britain, Poland and Germany as well as a global sales network, the company is active in more than 40 countries on every continent and has an export rate of around 90 %, placing it among the world‘s leading manufacturers in this growing, future-orientated industry.

UNTHA international

In addition to our headquarters in Kuchl near Salzburg and an Office in Vienna, we have four independent sales subsidiaries in the USA, Great Britain, Germany and Poland.

Where we come from

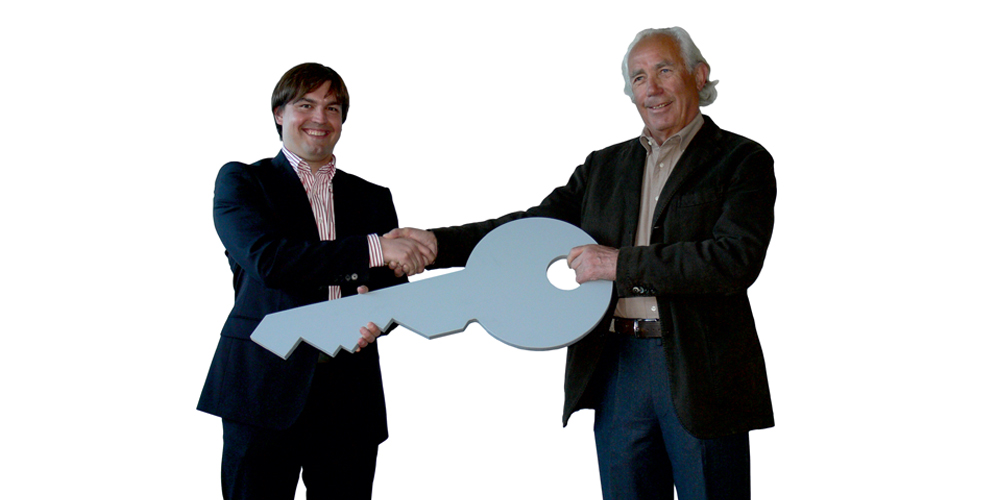

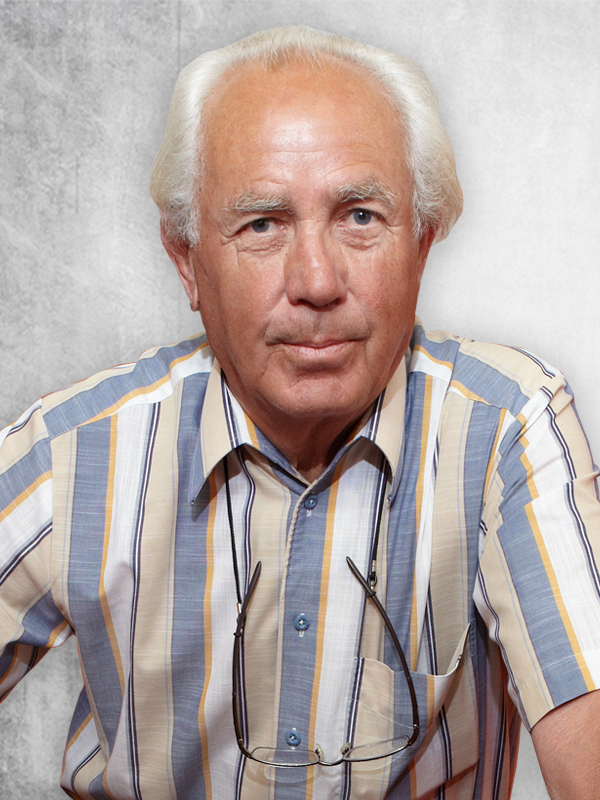

Anton Unterwurzacher sets up a metalworking shop with five employees in Kuchl near Salzburg.

I didn’t really think about the direction the business would take. My goal was always to develop products according to customer specifications. The customer was always king. We certainly had to pay our dues along the way – the fact that the business developed as it did was partially due to luck.

Anton Unterwurzacher

Founder of UNTHA shredding technology

The success story continues

UNTHA GENIUS: The intelligent condition monitoring tool GENIUS, newly developed by UNTHA, is the brain of every shredding machine. All the necessary operating and process data can be called up online in real time.

ZR2400: UNTHA presents a new 2-shaft shredder for the processing of waste and metals. This shredder was specially designed for coarse pre-shredding.

Customer service: The UNTHA Service Competence Center guarantees the extensive services that existing customers can expect from their reliable partner.

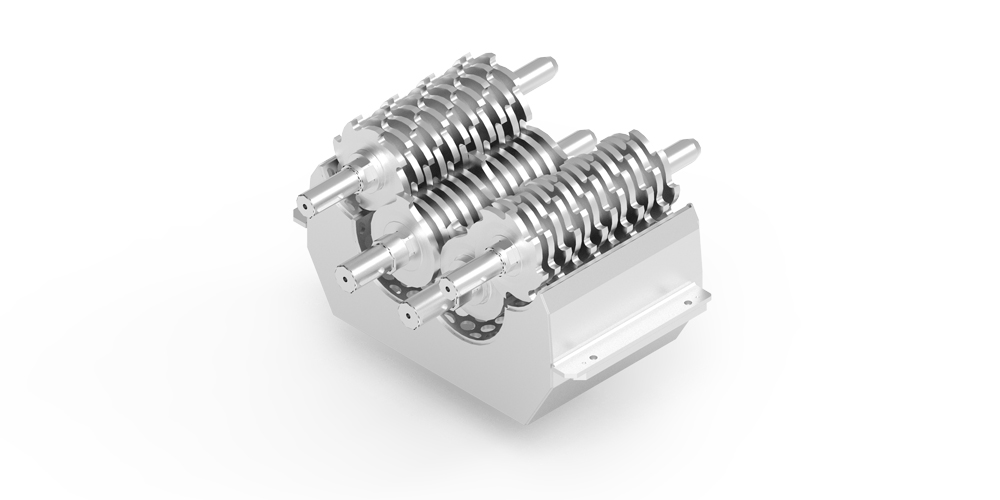

New RC cutting system: With the RC cutting unit for the XR class, UNTHA has developed a new type of knife geometry with improved intake behavior, with which, among other things, particularly high throughput rates are possible.

Would you like a comprehensive overview of the past, present and future of UNTHA? You can download the Festschrift here.