Professionally carried out by our experts

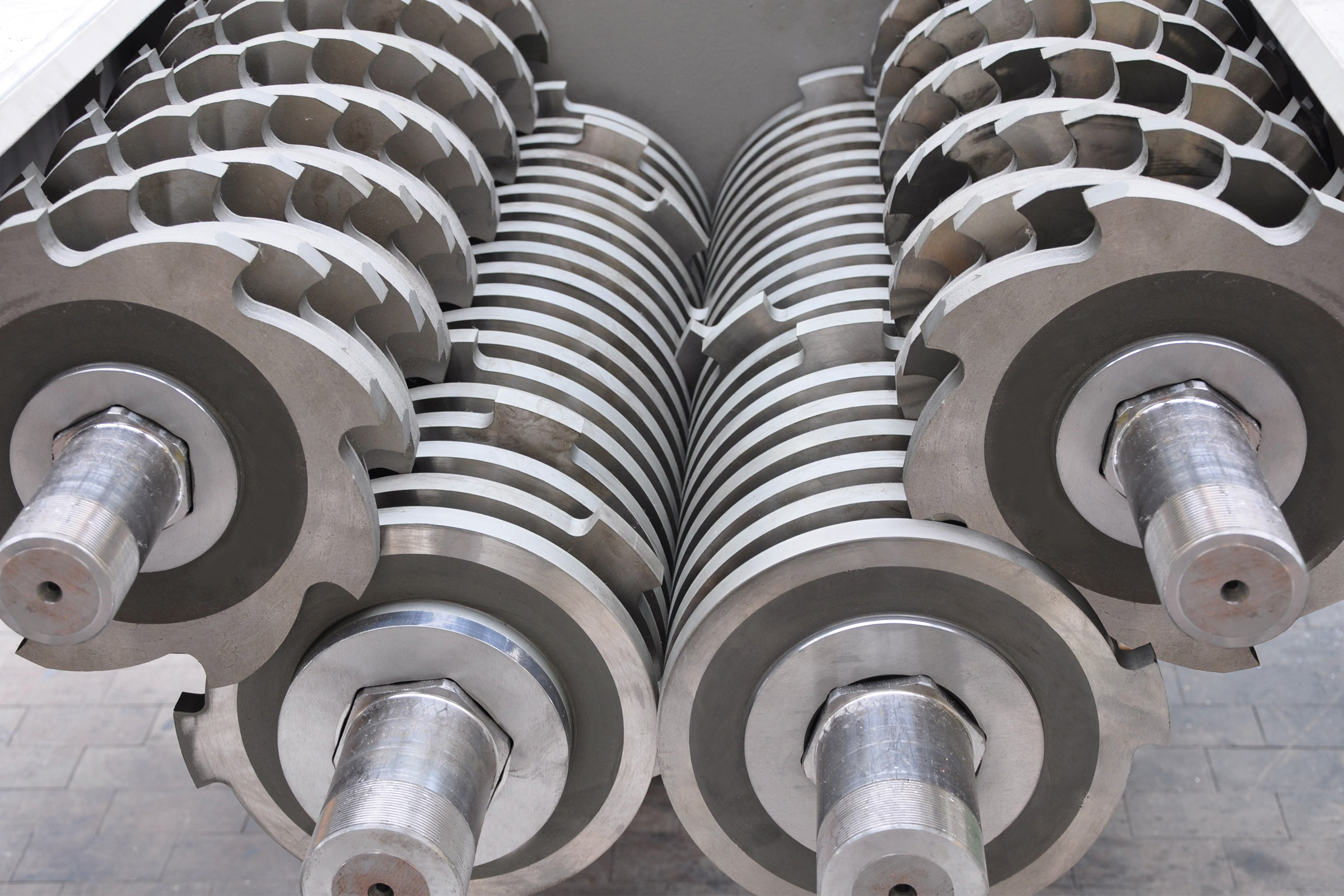

Change of cutting units, change or rotation of indexable cutting inserts

Every cutting unit in a shredder wears out in the course of its service life, and with a certain degree of wear, is no longer economical. Throughput rates fall, use of electricity and the cost of personnel rise. UNTHA service engineers have the necessary specialist tools and know best how to change or rotate your cutting units quickly and professionally. After a brief downtime period, the shredder will soon be available again.

What benefits can you expect?

As part of the cutter change, a maintenance and service inspection may be performed during which all relevant components are checked for wear.

Thanks to our professional, excellently trained service engineers, downtimes are kept to a minimum.

A new cutter configuration may optimise production. Our service will reduce the ongoing operating costs at the same time.

You would like to receive more information on our UNTHA services, get in touch with our service experts or book this service directly? Then you have come to the right place!

Everything from a single source

With UNTHA Lifetime Support, we provide you with support throughout the entire product life cycle and offer you comprehensive service products for maximum machine availability. Be it regular maintenance work, providing original spare parts and wearing parts or our individual carefree packages, we ensure that UNTHA machines are ready for use at all times and do what they were built for – namely reliable shredding.