Recycling 100% of waste wood

Wood is one of the most important renewable raw materials. If everything is done right, up to 100 percent of it can be sensibly utilised. Initially in the production of wooden houses and walls, furniture and window frames. Moreover, the residual wood can also be reused if it is processed accordingly – for example as biomass for energy and heat generation. The UNTHA wood shredders help to make the recycling and disposal of waste wood more efficient and cost-effective. They help customers to improve their carbon footprint and to supply their company buildings with self-produced energy, while also reducing the need for storage space and personnel to handle the wood waste.

UNTHA develops and produces shredding technology for joinery and carpentry businesses, sawmills and the wood processing industry. But wholesalers and transport companies that handle large quantities of wooden pallets also rely on UNTHA wood shredders.

Waste wood processing plays an important role in ensuring smooth production processes, not to mention the efficient use of resources and energy. In times of rising energy costs, waste wood recycling is becoming more and more relevant. ‘Our customers are increasingly thinking about how they can make their processes more efficient and sustainable. In this context, the processing of residual wood plays a particularly important role,' says Josef Gruber, Head of Global Sales and Business Development BU Wood at UNTHA. Ideally, the residual wood should not represent a separate work step in the company in order to conserve personnel resources. ’Wood scraps go directly from the production area to the shredder, are automatically processed and then go directly to the central heating boiler via the corresponding conveyor system. The warmth produced can be used to supply heat to production facilities, drying chambers, offices and nearby residential units. Many of our customers have become energy self-sufficient in this way and save a lot of time and money,' Josef Gruber further explains.

Customised shredding solutions

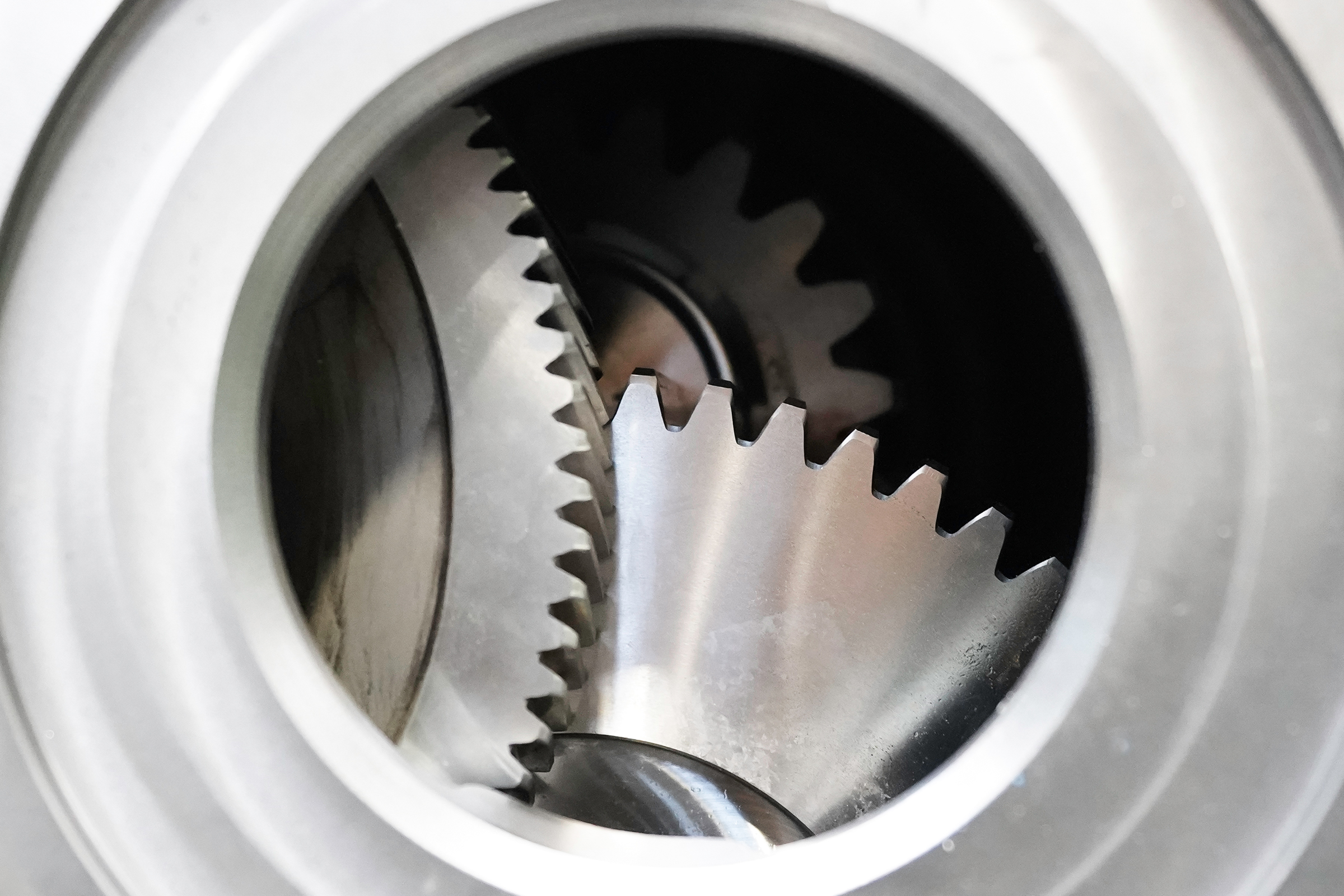

The first step in the thermal recycling of waste wood is to shred the material into homogenous wood chips. UNTHA wood shredders can be used as stand-alone solutions or integrated into fully automated plants. Thanks to their compact design and innovative technology, they can be seamlessly integrated into any operation and ensure that all types of waste wood are processed efficiently. The UNTHA product portfolio includes a variety of different solutions: from the RS series – robust 4-shaft shredders for intensive continuous operation – to the LR series – with its powerful 1-shaft shredders for particularly large quantities of residual wood. UNTHA also offers a wide range of conveyor technology, metal separators and additional features that ensure even greater efficiency and safety.

‘Wood is a valuable resource, which is why it is important to use it responsibly and efficiently. UNTHA wood shredders are capable of efficiently shredding all types of waste wood, which can then be used as combustion material or pressed into pellets. This way, 100 per cent of the wood is recycled, which is both economically and sustainably sound,’ says Josef Gruber in conclusion.

Download pictures (Reprint free of charge for press purposes, picture credit: UNTHA shredding technology GmbH) https://untha.canto.de/b/K1KFM

Photo 1: Josef Gruber, Head of Global Sales and Business Development BU Wood at UNTHA

Photo 2: LOC Holz relies on two UNTHA wood shredders – model LR1400

Photo 3: The central warehouse of the Raiffeisenverband (RVS) uses a practical UNTHA plant concept with an LR1400

Photo 4: The Kienpointner carpentry workshop uses a pit-mounted UNTHA LR1000.

Photo 5: Binderholz relies on nine RS30 machines, which were installed directly in the processing lines.