References

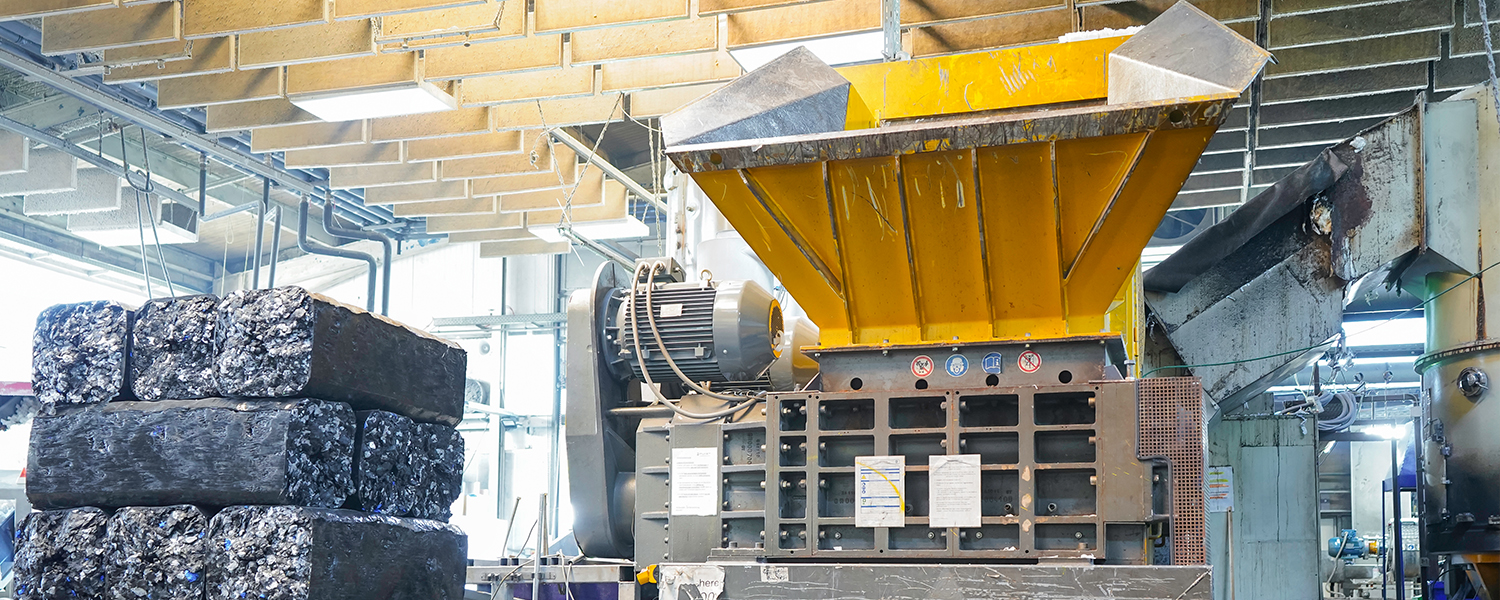

R.Plast uses two UNTHA RS100 machines as pre-shredders. These ‘rotor scissors’ are capable of shredding even the toughest and most tear-resistant materials, preparing them for extruder processing. The shredders are also equipped with a conveyor system that transports the material from the shredders to the subsequent processing lines. Both shredders can be loaded by forklift.

R.PLAST is a recycling and trading company for primary and secondary thermoplastics. For 35 years, the company has been ensuring that production residues from the plastic manufacturing and processing industry are recycled into high-quality ground material, regranulates and compounds.

Due to their composition, PE and PP bales and solid plastics can be very challenging. Not every shredder can handle them. R.Plast was therefore looking for a shredding solution that could quickly and efficiently shred particularly tear-resistant and robust materials so that they could then be processed in extruders. It should also be possible to integrate the new shredders into the existing machine peripherals.

REQUIREMENTS

Cutting system – ‘rotor scissors’

Efficient pre-shredding

Adaptation to different materials

Intensive continuous operation

R.Plast opted for the RS100 from UNTHA after an extensive material test. This 4-shaft shredder has a cutting system − ‘rotor scissors’ − that uses a cutting principle to shred even particularly tear-resistant materials with ease and is resistant to foreign objects. An optional feed system ensures that even bales and rolls of material can be optimally grasped and shredded by the cutting unit. The UNTHA RS100 can be operated with or without a perforated screen, depending on the requirements for the output material. Perforated screens can also be added or exchanged at a later date. At R.Plast, the two RS100 machines are used as primary shredders in multi-shift operation. The output material is processed into granulate in downstream extruders, which is then reprocessed in injection moulding plants and the automotive industry.

UNTHA carried out test runs with the RS100 on our materials and the results were phenomenal. It quickly became clear to us that this was the right shredder for us. We now have two UNTHA RS100 machines in operation at the beginning of our recycling process.

Rolf Treutlein

Managing Director & Shareholder R.PLAST Kunststoffaufbereitungs- und Handels-GmbH